About Pump WINNER 4N

4″ submerged sump pump with floating impellers with front shim, suitable for handling water in general and also for horizontal operation

Features

- Silent

- Practical and easy to use

- Suitable for horizontal operation

description Pump WINNER 4N

4″ submerged sump pump equipped with a special system of floating impellers with front shim, which allows it to operate even in particularly heavy conditions without blocking and which gives the electric pump a low axial load.

It is a very quiet product that boasts high hydraulic efficiency that can be coupled with motors in water bath or oil bath.

It can also be used in a horizontal position.

For further technical information see the Databook

- Handling of clear water in wells

- Pressurisation of clean water for agricultural, domestic or industrial use

- Irrigation

- Handling of water in general

Overview of technical data WINNER 4N

| Flow rate | Up to 21 m³/h |

| Total head | Up to 370 m |

| Max. temperature of the liquid | +40°C (depends on the maximum motor temperature) |

| Poles | 2 |

| Insulation class | F (OY), B (WY) |

| Protection degree | IP 68 |

| Voltage | Single-phase 1~230V ±10% OYM Three-phase 3~380-415V ±10% OY Single-phase 1~230V -10%+6% WYM Three-phase 3~380-415V -10%+6% WY Three-phase 3~400V -10%+6% WY |

| Max. immersion | 350 m with motor in water bath 150 m with motor in oil bath |

| Max. sand content | 50 ppm |

Material Pump WINNER 4N

| Impeller | Ixef® for 4N1 – 4N2 – 4N4 – 4N7, PC reinforced with glass fibres for 4N10, 4N15 |

| Shaft | Stainless steel AISI 304 (EN 1.4301) |

| Outer casing | AISI 304 (EN 1.4301) |

| Discharge casing | ASTM CF8 |

| Motor connection | AISI 304 (EN 1.4301) |

pump DWO

4” submersible centrifugal pump

4” submersible centrifugal electric pump in AISI 304 with floating impellers with frontal shim.

Outer casing, shaft and valve are in AISI 304. Discharge casing in EN 1.4308 (ASTM CF8). The impeller is in Ixef® (glass fibre reinforced thermoplastic) for 4N1 – 4N2 – 4N4 – 4N7 models, in glass fibre reinforced polycarbonate for 4N10 – 4N15 models, PPE+PS diffuser reinforced with glass fibres. Particularly recommended for the movement of clear water in wells, the pressurisation of clean water for agricultural, domestic or industrial use, or for the irrigation and movement of water in general

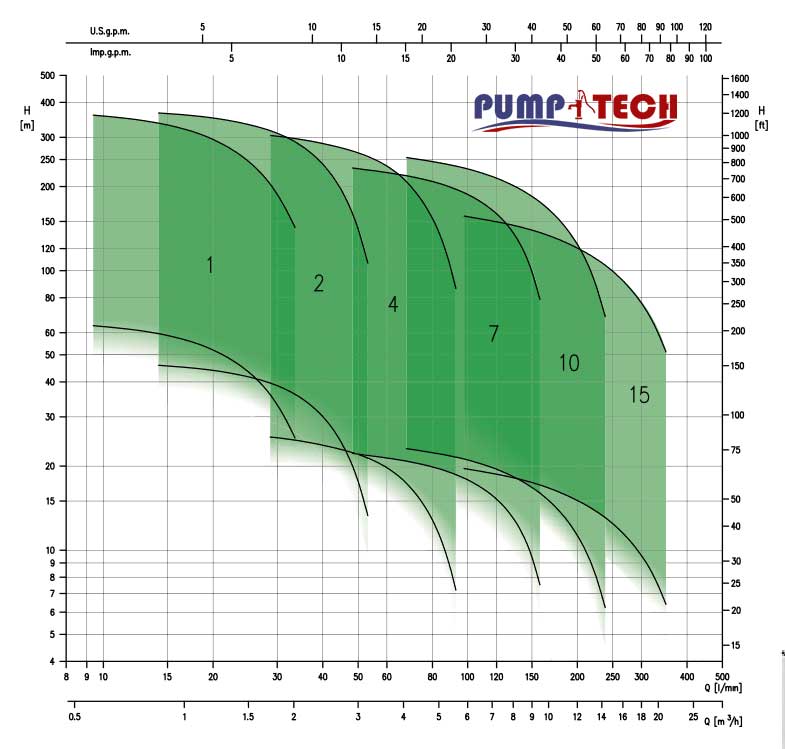

PERFORMANCE CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906 Annex A

The curves refer to effective speed of asynchronous motors at 50 Hz

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity

of ν = 1 mm2/s (1 cSt)

The continuous curves indicate the recommended working range. The dotted curve is only a guide.

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best efficiency point.

Symbols explanation:

Q = volume flow rate

H = total head

P2 = pump power input (shaft power)

η = pump efficiency

NPSH = net positive suction head required by the pump

MEI = minimum efficiency index

The minimun efficiency index (MEI) is a measure of the quality of a pump size in respect to its mean efficiency. The minimum efficiency index is based on the hydraulic efficiency and on the head at the best efficiency point.

The efficiency of a pump with trimmed impeller is usually lower than that of a pump with the full impeller diameter. The trimming of the impeller will adapt the pump to a fixed duty point, leading to reduced energy consumption. The minimum efficiency index (MEI) is based on the full impeller diameter.

The operation of these water pumps with variabile duty points may be more efficient end economic when controlled, for example, by the use of a variable speed drive that matches the pump duty to the system.

Q=Capacity | Motor | Pump type | ||||||||||||

95 | 75 | 55 | 45 | 35 | 30 | 25 | 20 | 15 | 10 | 0 | l/min | |||

5.7 | 4.5 | 3.3 | 2.7 | 2.1 | 1.8 | 1.5 | 1.2 | 0.9 | 0.6 | 0.0 | m/h | HP | kw | |

H=Total Head | ||||||||||||||

– – – – – – | – – – – – – | – – – – – – | – – – – – – | 25 38 50 71 101 143 | 36 54 72 102 144 204 | 46 68 91 129 182 258 | 54 80 107 152 214 303 | 60 89 119 169 238 337 | 64 95 127 180 254 360 | 67 100 133 189 266 377 | 0.5 0.7 1.0 1.5 2.0 3.0 | 0.37 0.55 0.75 1.10 1.50 2.20 | 4N1- 12 4N1- 18 4N1- 24 4N1- 34 4N1- 48 4N1- 68 | |

– – – – – – – | – – – – – – – | 13 19 27 38 53 76 106 | 26 38 53 75 105 150 210 | 36 52 72 103 144 206 289 | 40 57 79 113 158 226 317 | 42 60 85 121 169 242 338 | 44 63 89 127 178 254 355 | 46 66 92 131 183 262 367 | – – – – – – – | 49 69 97 139 194 277 388 | 0.5 0.7 1.0 1.5 2.0 3.0 4.0 | 0.37 0.55 0.75 1.10 1.50 2.20 3.00 | 4N2- 7 4N2- 10 4N2- 14 4N2- 20 4N2- 28 4N2- 40 4N2- 56 | |

7 13 16 23 32 49 65 86 | 16 27 35 51 70 105 140 187 | 21 37 48 69 96 144 192 256 | 23 41 52 75 104 157 209 278 | 25 43 56 80 111 167 223 297 | 25 44 57 83 114 171 229 305 | – – – – – – – – | – – – – – – – – | – – – – – – – – | – – – – – – – – | 28 49 63 90 125 188 250 334 | 0.5 0.7 1.0 1.5 2.0 3.0 4.0 5.5 | 0.37 0.55 0.75 1.10 1.50 2.20 3.00 4.00 | 4N4- 4 4N4- 7 4N4- 9 4N4- 13 4N4- 18 4N4- 27 4N4- 36 4N4- 48 | |

Q=Capacity | Motor | Pump type | ||||||||||||

350 | 320 | 280 | 240 | 200 | 160 | 130 | 100 | 70 | 50 | 0 | l/min | |||

21.0 | 19.2 | 16.8 | 14.4 | 12.0 | 9.6 | 7.8 | 6.0 | 4.2 | 3.0 | 0.0 | m/h | HP | kw | |

H=Total Head | ||||||||||||||

– – – – – – – – | – – – – – – – – | – – – – – – – – | – – – – – – – – | – – – – – – – – | 8 11 15 23 32 43 56 79 | 14 21 28 42 60 81 105 147 | 18 27 36 54 77 104 136 190 | 21 31 42 62 88 120 156 219 | 22 33 44 67 94 128 167 233 | 25 37 50 74 105 143 186 260 | 0.7 1.0 1.5 2.0 3.0 4.0 5.5 7.5 | 0.55 0.75 1.10 1.50 2.20 3.00 4.00 5.50 | 4N7- 4 4N7- 6 4N7- 8 4N7- 12 4N7- 17 4N7- 23 4N7- 30 4N7- 42 | |

– – – – – – – – | – – – – – – – – | – – – – – – – – | 7 10 13 20 28 38 50 69 | 13 19 25 38 53 72 94 131 | 17 25 34 51 72 97 127 177 | 19 29 39 58 82 11 145 203 | 21 32 43 64 91 123 161 225 | 23 35 46 70 99 133 174 244 | – – – – – – – – | 26 39 52 78 111 150 195 273 | 1.0 1.5 2.0 3.0 4.0 5.5 7.5 10.0 | 0.75 1.10 1.50 2.20 3.00 4.00 5.50 7.50 | 4N10- 4 4N10- 6 4N10- 8 4N10- 12 4N10- 17 4N10- 23 4N10- 30 4N10- 42 | |

6 10 14 21 27 38 | 8 13 19 27 36 50 | 11 16 24 35 46 65 | 13 20 29 43 56 78 | 15 23 34 49 64 91 | 17 26 39 56 73 103 | 18 28 41 60 78 110 | 20 29 44 64 83 118 | – – – – – – | – – – – – – | 22 33 50 72 94 133 | 1.5 2.0 3.0 4.0 5.5 7.5 | 1.10 1.50 2.20 3.00 4.00 5.50 | 4N15- 4 4N15- 6 4N15- 9 4N15- 13 4N15- 17 4N15- 24 | |