VPCP Main applications

The Packo VPCP pump range is specifically designed for damage-free pumping of potatoes and vegetables but also seafood such as mussels, cockles and shrimp.

The VPCP pump can be used in Belgian fries process lines, transport of vegetables to blanching lines as well as for transport of pasta from pasta cookers.

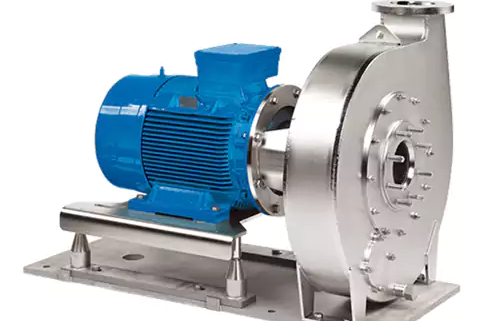

VPCP Design

The Packo stainless steel pumps of the VPCP series have an extremely large passage and thanks to its specially designed single vane this type of product pump is the reference in soft and damage free pumping of vegetables, potatoes, mussels, shrimps, etc. They are used in vegetable and potato industry but also in sea fruit business.Due to the close-coupled system, these pumps are very easy and quick to maintain, take up little floor space and achieve the highest efficiency. This high efficiency at BEP also ensures damage-free pumping of the various possible products in transport, elevation or cutting applications. Standard electropolish surface treatment in combination with a cleanable design makes the pump corrosion resistant and CIP cleanable. This complete picture makes this pump a winner in terms of Total Cost of Ownership.

VPCP benefits pump

- Gentle and damage-free pumping

- Easy maintenance: short downtimes

- Extremely large passage

- Electropolished stainless steel 304L: no rusting & easy to clean

- Monobloc design: space saving

VPCP Description

The Packo stainless steel pumps of the VPCP series have an extremely large passage and thanks to its specially designed single vane this type of product pump is the reference in soft and damage free pumping of vegetables, potatoes, mussels, shrimps, etc. They are used in vegetable and potato industry but also in sea fruit business.Due to the close-coupled system, these pumps are very easy and quick to maintain, take up little floor space and achieve the highest efficiency. This high efficiency at BEP also ensures damage-free pumping of the various possible products in transport, elevation or cutting applications. Standard electropolish surface treatment in combination with a cleanable design makes the pump corrosion resistant and CIP cleanable. This complete picture makes this pump a winner in terms of Total Cost of Ownership.

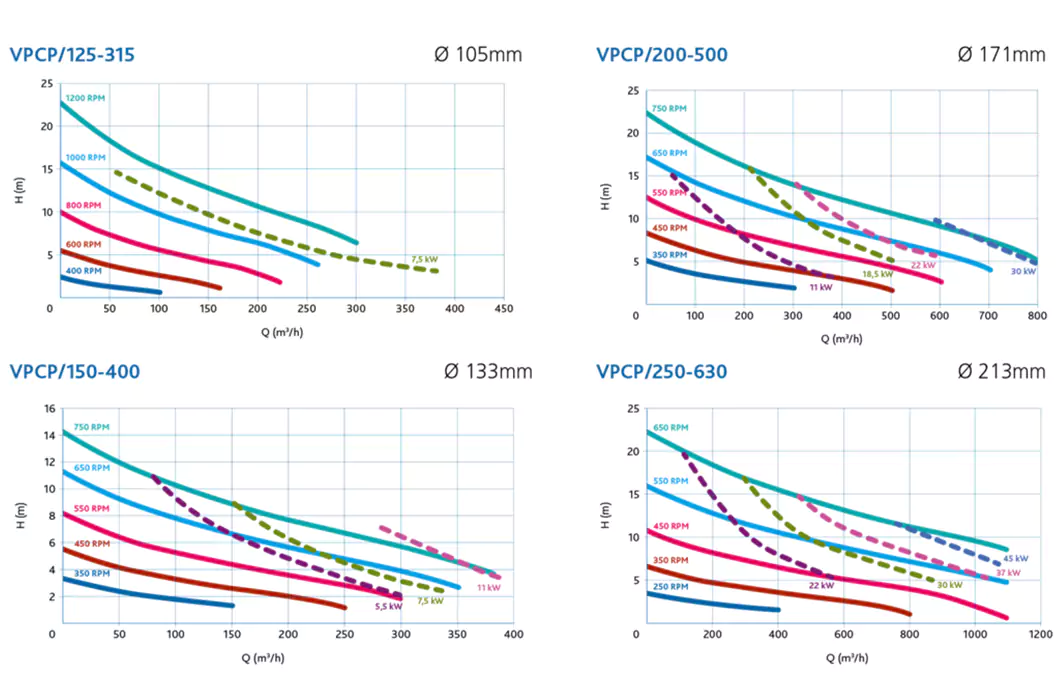

VPCP Curve

Overview of technical data VPCP

| Max. flow | 1000 m3/h |

| Differential head | 20 m wc |

| Max. Inlet pressure | 4 bar |

| Viscosity | 100 cP |

| Max. temperature | 80 °C |

| Impeller type | Special designed vane |

| Max. free passage | 213 mm |

| Max. drive power | 55 kW |

| Speed | 1200 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 304 or similar |

| Mechanical seal configuration | Single |

| Available material O-ring | NBR (FDA) |

| Connections | Industrial |

| Surface finish | Industrial finish: welds are not hand polished. Final surface treatment: electropolished |

| Certificates | 1935/2004 EC. FDA. EAC |