Main applications vitalobe

- Breweries

- Creameries

- Food and beverages

- Industry engineering

- Pharmaceutical/Biotechnology

- Soft drinks

- Sugar

Technical data

- Q max 300.0 m³/h

- H max 150.0 m

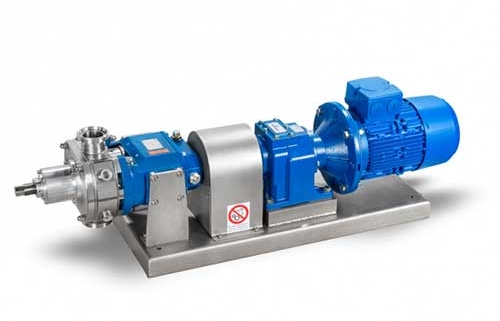

Design vitalobe

Sturdy rotary lobe pump in hygienic design, bi-directional operation possible, horizontal or vertical orientation of connections. Hygienic design, highly CIP/SIP-compatible due to its almost complete lack of dead volume or narrow clearances. All wetted components made of 1.4404/1.4409 (AISI 316L/CF3M) stainless steel; various rotor types, shaft seals and process connections available. Installed as a pump set with geared standardised motor. Vitalobe is EHEDG-certified. The pump elastomers comply with FDA standards and EN 1935/2004. Accessories include trolley, heatable casing or casing cover and overpressure protection unit. ATEX-compliant version is available.

Application pump vitalobe

Hygienic and gentle handling of sensitive or high-viscosity fluids in the food, beverage and pharmaceutical industries, the chemical industry and general process engineering.

Drive pump vitalobe

Speed and torque of the motor are adjusted to the values required for the pump by means of a gear unit.

▪ Surface-cooled KSB squirrel-cage motor

▪ Type of construction B5, V1

▪ Thermal class F

▪ 3 PTC thermistors

▪ Duty cycle: continuous duty S1

▪ Winding 50 Hz, 220 – 240 V / 380 – 420 V ≤ 2.20 kW; 380 – 420 V / 660 – 725 V ≥ 3.00 kW

Desing Details pump vitalobe

Design

▪ Standard design with materials to Regulation (EC) No. 1935/20041)

▪ Design to ATEX

Design

▪ Hygienic rotary lobe pump

▪ Long-coupled design

▪ In-line design

▪ Wetted parts made of stainless steel 1.4404/1.4409 (AISI 316L/CF3M)

▪ Cleanability levels 1 + 2 to EN 13951 for Vitalobe design B

▪ Cleanability levels 3 + 4 to EN 13951 for Vitalobe

design BB

Pump casing

▪ Rotor casing

Impeller type

▪ Tri-lobe, bi-lobe, gear-shaped or bi-wing rotor

Bearings

▪ Size 100: deep groove ball bearing and needle bearing

▪ Sizes 105 to 115: tapered roller bearings

▪ Sizes 215 to 490: double tapered roller bearings

▪ Sizes 550 to 680: cylindrical roller bearing and two-row deep groove ball bearings

Shaft seal

▪ Single mechanical seals with or without flushing system to EN 12756

▪ Double mechanical seals to EN 12756

Different seal types

▪ Seal type Y: external single mechanical seal, with or without flushing system

▪ Seal type Q: external double mechanical seal in back-toback arrangement

▪ Seal type L: shaft seal ring, single or double

Overview of technical data vitalobe

| Q (50Hz) | 0.1 – 300.0 (m³/h) |

| H (50Hz) | 0.1 – 150.0 (m) |

| Type of bearing | Rolling element bearings |

| Drive | Electric motor |

| Drive frequency | 50 Hz /60 Hz |

| Connection to power supply | 230/400V, 400/690 V, 3~ |

| Heatable | Yes |

| Type of installation | Long-coupled |

| Type of coupling | Direct |

| Type of lubrication | Product lubrication |

| Max. permissible fluid temperature | 200.0 (°C) |

| Shaft material (EN standard) | 1.4404 (AISI 316L) |

| Suitable for drinking water | Yes |

| Type of connection | Screw-ended, flange |

| Casing material (EN standard) | 1.4409 (AISI CF3M) |

| Installation position | Horizontal |

| Shaft seal type | Shaft seal ring, Mechanical seal |

| Main applications | Industry and process engineering, Food,beverages and pharmaceutical industry |

| Maximum discharge-side pressure | 30.0 (bar) |

| Type of installation | Transportable, Stationary |

| Maximum speed of rotation | 1500.0 (1/min) |