About Pump PRA – PRN

PRA peripheral pump with cast iron pump body and motor bracket, also available in the nickel-plated version (PRN 0.50 single-phase). Practical, compact and easily transportable.

Features

- Nickel-plated version available

- Lightweight and easily transportable

- Practical and easy to use

- Silent

description Pump PRA – PRN

PRA peripheral pump with cast iron body and support, also available in the nickel-plated version (PRN 0.50 single-phase).

PRA-PRN electric pumps are practical, compact and easily transportable.

For further technical information see the Databook

- Domestic use

- Boiler power supply

- Autoclave units

Overview of technical data PRA – PRN

| Flow rate | from 0.3 to 4.2 m³/h |

| Total head | From 12 to 88 m |

| Max. working pressure | 6 bar PRA/PRN 0.50 7.5 bar PRA 0.80 12 bar for the rest of the range |

| Max. temperature of the liquid | +80°C |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP44 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~230/400V ±10% |

Material Pump PRA – PRN

| Pump body | Cast iron |

| Impeller | Brass Nickel-plated brass (PRN) |

| Shaft | AVZ for PRA 0.50 AISI 303 (EN 1.4305) for the rest of the range |

| Mechanical seal | Carbon/Ceramic/NBR (standard) |

| Motor support | Cast iron |

pump PRA – PRN

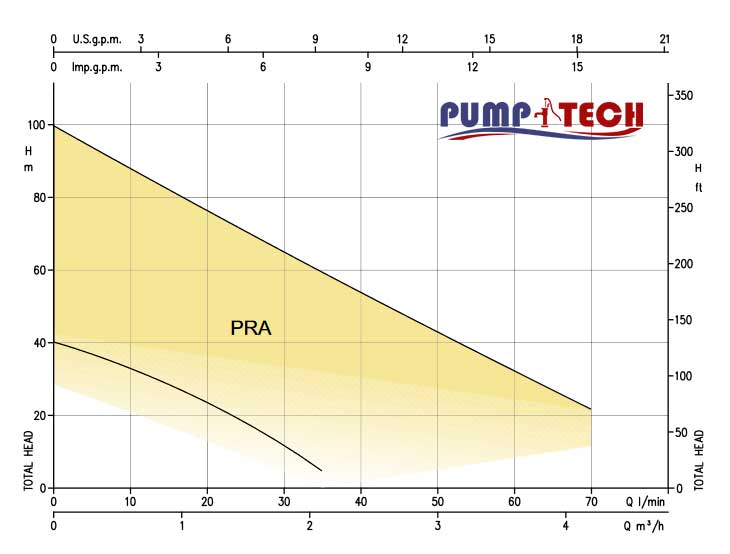

PERFORMANCE CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906 Annex A

The curves refer to effective speed of asynchronous motors at 50 Hz

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity

of = 1 mm2/s (1 cSt)

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best efficiency point.

Symbols explanation:

Q = volume flow rate

H = total head

Peripheral electric pumps with cast iron body and support particularly suitable for domestic use, boiler supply, autoclave units, etc. The shaft is in AVZ for the PRA 0.50 model, in AISI 303 for the rest of the range (part in contact with the liquid).

Brass impeller and mechanical seal in Ceramic/Carbon/NBR. The motors combined with PRA pumps are IE3 2-pole high energy efficient asynchronous motors starting from 0.75 kW

Technical

- Total head from 5 to 88 m

- Capacity from 0.3 to 4.2 m3/h

- Maximum operating pressure:

– 6 bar for PRA 0.50

– 7.5 bar for PRA 0.80

– 12 bar for the rest of the range - Maximum liquid temperature 80°C

| Pump type | KW | Capacitor | Q=Capacity | ||||||||||

| Single-phase 230v 50hz | Three-phase 230/400v 50hz | µF | Vc | l/min | 5 | 10 | 15 | 20 | 35 | 50 | 65 | 70 | |

| m/h | 0.3 | 0.6 | 0.9 | 1.2 | 2.1 | 3 | 3.9 | 4.2 | |||||

| H=Total Head | |||||||||||||

| PRA0.5 M | PRA0.5 T | 0.37 | 10 | 450 | 37 | 33.3 | 28.7 | 23.7 | 5 | – | – | – | |

| PRA0.8 M | PRA0.8 T | 0.6 | 16 | 450 | 56 | 50.7 | 45.1 | 39.8 | 25 | 12 | – | – | |

| PRA1 M | PRA 1 T | 0.75 | 20 | 450 | 62 | 54.4 | 47 | 40.4 | 24.3 | 13 | – | – | |

| PRA 1.5 M | PRA 1.5 T | 1.1 | 35 | 450 | – | 81 | 76.9 | 71.9 | 55.8 | 37.9 | 18 | – | |

| PRA 2 M | PRA 2 T | 1.5 | 40 | 450 | – | 88 | 82.9 | 77 | 59.8 | 43.3 | 27.4 | 22 | |