Main applications lcc-r

- Ash removal

- Hard Rock mining

- Industrial Process

- Mineral Mining

- Mining

- Slurry

Technical data

- Q max 2,455.0 m³/h

- H max 50.0 m

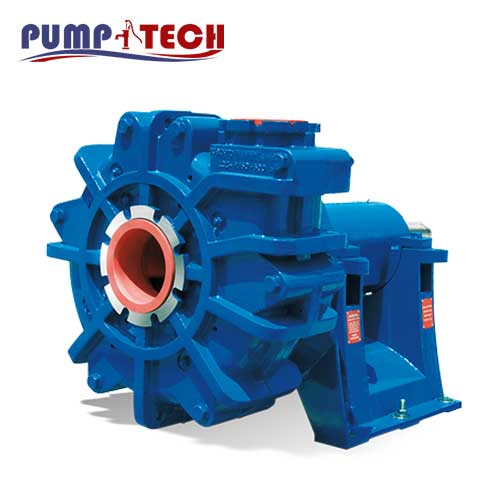

Design lcc-r

Interchangeable rubber-lined or part-metal design allows adaptation of existing pumps to new applications by simply exchanging the pump wet end.

Application pump lcc-r

The pumps are suitable for moderate heads, fine particles and highly corrosive slurries.

Overview of technical data lcc-r

| Q (50Hz) | 25.0 – 2,455.0 (m³/h) |

| H (50Hz) | 5.0 – 50.0 (m) |

| Type of bearing | Rolling element bearings |

| Type of drive | Electric motor, turbine, I.C. engine |

| Type of coupling | Direct, Gear, None, Variable speed coupling, Jack shaft / Belt drive, Float switch, Bubbler system |

| Type of lubrication | Grease / Oil lubrication |

| Pump set location | Dry installed, Wet well, Dry installed, floodable |

| Free passage | 107.0 (mm) |

| Shaft seal type | Gland packing, Mechanical seal, Hydrodynamic seal |

| Main applications | Industry and process engineering, Water, Waste water / sewage, Energy, Mining / Dredges, Shipping / Shipbuilding |

| Type of installation | Transportable, Stationary |