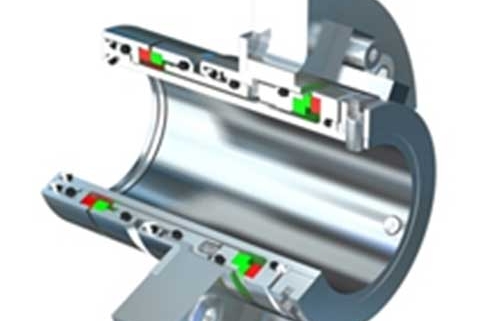

O-ring Pusher seals | Heavy-duty Dual-cartridge Seals

Features mechanical seal type sb2a

- California Residents: PROPOSITION 65 WARNING

- Seal faces are installed using a patented heat shrink process ensuring correct, distortion-free face alignment at all recommended temperatures.

- The springs are located in the stationary body of the seal in the seal water (barrier fluid). The seal water washes the springs, preventing process chemical corrosion and reduces the risk of the springs becoming clogged. Shaft misalignment does not vibrate or wear out the O-rings.

- PTFE slot rings replace the traditional O-rings in places where they are exposed to the product, preventing sticking.

- Protected faces, the seal face carriers are driven by machined fits, preventing metal stress from distorting the face.

- Patented double-balanced design allows the use of both pressurized and unpressurized seal water (barrier/buffer fluid) and prevents face overload.

- SB2 series seals will accept ± 0.080″/± 2.0mm axial movement (shaft end play) during normal operation due to their piston design. Impeller adjustments do not affect face stress or spring strength.

Recommended Applications type sb2a

- Process pumps

- Other rotating equipment

- Catalog Mechanical seal Type SB2A John Crane

About Mechanical seal type sb2a

The Safeseal Type SB2A is a dual-cartridge seal. Its double-balanced design ensures the reliability and longevity of the seal in the most demanding conditions. The Type SB2A seal is ideal for use with environmentally hazardous and abrasive fluids, most often used in pumps in pulp mills, minerals processing and other slurry duties up to 40% solids by weight and a solids hardness of 8 Mohs. The Type SB2A seal is widely used with other process equipment including agitators.

Several variants of the design available for different services:

Type SB2 — designed for DIN standard dimensions

Type SB2A-PR — designed for ANSI standard dimensions, including integrated pumping device

Operating range mechanical seal type sb2a

| Temperature Limits | 350°F/180°C |

|---|---|

| Pressure Limits | Process pressure: 290 psi(g)/20 bar(g) Barrier fluid: 215 psi(g)/15 bar(g) |

| Speed Limits | 65fps/20m/s |

| Standard Materials | Seal faces: SiC/Carbon or SiC/SiC O-rings: PTFE, EPDM, Viton, FFKM Metals: AISI 329 and 316 standard, titanium, Hastelloy, UHB, 904, SAF 2507 for sea water applications Springs: Nimonic steel |