Features mechanical seal type 83

- California Residents: PROPOSITION 65 WARNING

- Low buffer gas consumption.

- Low wear for longer life and improved reliability.

- Cartridge design for easy installation.

- Universal design independent of shaft rotation.

- Unique carbon bushing segment design with self-adjusting hydropads.

- Incorporates biased flow path to further reduce the risk of bearing oil migration.

- Specially designed joint between the carbon bushing segments to minimize buffer consumption and bearing oil migration.

- Unique axial spring design accommodates shaft excursions.

Recommended Applications type 83

- Centrifugal compressors

- Other compressors

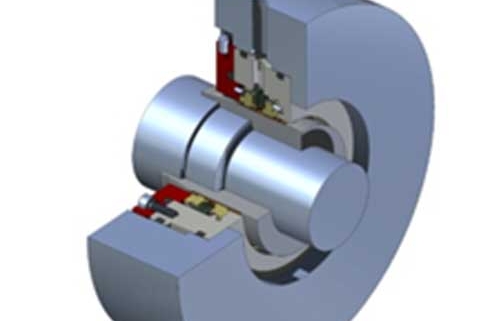

About Mechanical seal type 83

The Type 83 is a dual-segmented carbon bushing assembly designed to prevent the migration of bearing oil to the dry gas seal cartridge. Normally applied as a double arrangement with an inert buffer gas. When used in conjunction with the Type 28 dry-running gas seal, it provides a total sealing system that ensures separation of bearing oil and process gas in compressors.

Design Features mechanical seal type 83

- Low separation gas consumption

- Low wear for longer life and improved reliability

- Cartridge design for easy installation

- Universal design independent of shaft rotation

- Unique carbon bushing segment design with self-adjusting hydropads

- Specially designed segments minimize the separation gas consumption

Material mechanical seal type 83

- Bushing Segments: Carbon

- Axial Spring Stainless Steel

- Radial Springs Stainless Steel

- Housing Assembly Stainless Steel

- Secondary Sealing Elements Fluoroelastomer

Operating range mechanical seal type 83

- Temperature Limits

-20°F to 400°F/-30°C to 200°C - Pressure Limits

3 to 15 psi(g)/0.2 to 1.0 bar(g) - Speed Limits

430fps/130m/s - Size Limits

40mm to 375mm, with sleeve to fit all metric or imperial shafts

Product Description type 83

- The Type 83 is a contacting carbon bushing designed to isolate the bearing oil from the dry gas seal cartridge.

- Normally supplied as a complete seal cartridge, unique inner and outer segments are specifically designed to prevent oil migration and minimize wear.

- Nitrogen is normally injected between the two segmented bushings effectively creating a pressure barrier between the bearing and DGS cavity.

- Advanced materials and design ensure minimal wear and promote long life. Unlike many contacting separation seals the Type 83 is designed to operate on cryogenically dry nitrogen.