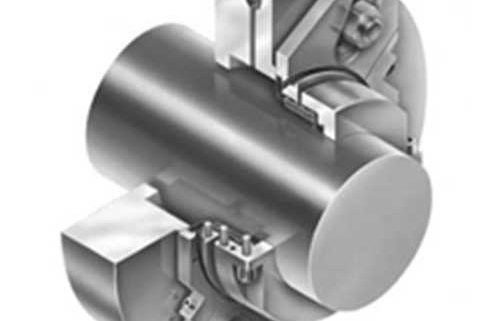

Split Seals | Heavy-duty Split Elastomer Bellows Seal for Agitators, Mixers and Pumps

Features mechanical seal type 37fs

- California Residents: PROPOSITION 65 WARNING

- The elastomer bellows compression ring provides extreme flexibility. Shaft deflections, angular misalignment, and run-outs are “tracked” by the seal without diminishing performance. Type 37FS split seals solve shaft motion and vibration problems that prohibit use of other seal designs.

- The compression ring acts as the spring, eliminating clogging problems seen in fibrous or abrasive services.

- The wide sealing surface of the sealing ring prevents leaks even on the most worn, pitted shafts.

- Rotating assembly self-aligns itself square with the shaft for true running.

- Fewer parts and simple design allow for easy installation. Seal can be readily mounted on worn shafts and out-of-square stuffing boxes — no modification of equipment is needed.

Recommended Applications type 37fs

- Process pumps

- Other rotating equipment

About Mechanical seal type 37fs

The Type 37FS fully split mechanical seal helps significantly reduce maintenance on larger, difficult-to-seal equipment. It is recommended for use on heavy-duty packed equipment that previously could not accommodate mechanical seals due to severe shaft run-out and vibration, difficult disassembly, worn-out equipment and similar problems. Its outside-mounted design allows it to be used on both vertical and horizontal applications.

The mechanical seals are ideal for use on large, heavy duty rotating shaft equipment such as mixers, agitators, and pumps. They are commonly found in the demanding pulp and paper, power generation, food and beverage, wastewater treatment and mining industries and are quickly and easily repairable, either on-site or at any John Crane Service Center.

Design Features mechanical seal type 37fs

- Maximum Flexibility — compression ring provides extreme flexibility. Shaft deflections, angular misalignments, and run outs are “tracked” by the seal without diminishing performance

- No springs — compression ring acts as the spring eliminating clogging problems seen in fibrous or abrasive services

- Slotted gland plates — long slots on gland plates allow the seals to be fitted to numerous pumps and other rotating equipment without adaptors

- Any shaft size possible — the rotating assembly can be machined to fit any size shaft

- No O-rings — wide sealing surface of the sealing ring prevents leaks even on the most worn, pitted shafts

- Self-aligning — the rotating assembly self-aligns itself square with the shaft for true running

- Easy installation — fewer parts and simple design allow for easy installation without the need for equipment modification

- Retaining ring ensures perfect face halves alignment and trouble-free startup

Material mechanical seal type 37fs

- Primary Ring: Carbon

- Mating Ring: Silicon Carbide

- Secondary Sealing: Buna-N

- Cord Segment: TFE Propylene

- Retaining Ring: Inconel®

- Clamp Ring: 316 Stainless Steel

Operating range mechanical seal type 37fs

| Temperature Limits | 180°F/82°C |

|---|---|

| Pressure Limits | 80 psi(g)/5.5 bar(g) |

| Speed Limits | 1800 rpm |

Product Description type 37fs

The Type 37FS fully split seals contribute to significantly reduced maintenance on larger, difficult-to-seal equipment. They are recommended for use on heavy duty, packed equipment that previously could not accommodate mechanical seals because of severe shaft runout and vibration, difficulty to disassemble, worn out equipment, and similar problems. Type 37FS seals are outside mounted and can be used on vertical and horizontal applications.

• For use on large, heavy duty rotating shaft equipment such as mixers, agitators, pumps

• For pulp and paper, power generation, food processing, wastewater treatment, mining and other demanding industries