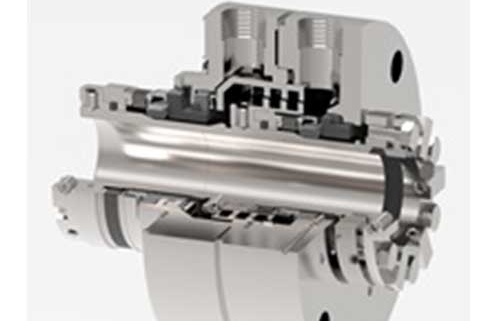

Features mechanical seal type 2609htc

- California Residents: PROPOSITION 65 WARNING

- Premium API 682/ISO 21049 qualified dual rotating cartridge seals Type C, Arrangement 2 and 3.

- These dependable cartridge seals utilize two impressive design innovations by incorporating high-temperature, corrosion-resistant sealing (HTC) and unique high-temperature, live-loaded (HTL) mating ring technology.

- HTL mating ring technology provides exceptional face stability by eliminating any thermal and mechanical forces that can contribute to seal face distortion.

- HTC primary seals incorporate specially designed pressure compensating seal faces and thermally compliant components that provide superior face stability at elevated temperatures.

- John Crane Sealide® advanced silicon carbide composite.

- ID and OD pressure capability; withstands reverse pressurization.

- All-Inconel metallurgy edge-welded metal bellows; meets NACE MR0175/MR0103.

Pumping ring standard

Recommended Applications type 2609htc

- Process pumps

About Mechanical seal type 2609htc

The Type 2609HTC and Type 3609HTC are dependable API 682/ISO 21049 cartridge seals that utilize two impressive design innovations by incorporating high-temperature, corrosion-resistant (HTC) sealing and unique high-temperature, live-loaded (HTL) mating ring technology in dual tandem seal arrangements. This new design vastly enhances seal face stability over conventional designs and can extend your MTBR in many services. These seals have ID and OD pressure capability and can withstand reverse pressurization. The seals come with a pumping ring standard, and the bellows have an all Inconel metallurgy for sealing the harshest high-temperature corrosive fluids. The Type 2609HTC is a dual unpressurized rotating bellows cartridge Type C, Arrangement 2. The Type 3609HTC is a dual pressurized rotating bellows cartridge seal Type C, Arrangement 3. Ideal for hot hydrocarbon refinery services.

Design Features mechanical seal type 2609htc

- API 682 qualified

- HTC technology

- HTL mating ring technology provides exceptional face stability

- Sealide-C* advanced silicon carbide composite

- ID and OD pressure capability — withstands reverse pressurization (Type 2609HTC/3609HTC)

- All-Inconel metallurgy — meets NACE MR0175/MR0103

- Dual scroll pumping device standard

- Optional segmented spring-loaded carbon throttle bushing for effective containment (Type 1604HTC)

- Retained mating ring available for vacuum service (Type 1604HTC)

Material mechanical seal type 2609htc

- Mating Ring Silicon Carbide Reaction Bonded

- Primary Ring Premium Grade Carbon

- Primary Ring Adapter Alloy 42 (UNS K94100)

- Adapter Alloy 625 (UNS NO6625)

- Bellows Alloy 718 (UNS NO7718)

- Adaptive Hardware 316 Stainless Steel

- Static Seals Flexible Graphite

Operating range mechanical seal type 2609htc

Temperature Limits

-100°F to 800°F/-75°C to 425°CPressure Limits

Vacuum to 300 psi(g)/20 bar(g)Speed Limits

5000fpm/25m/s

Product Description type 2609htc

- Type 2609HTC – Dual unpressurized rotating bellows cartridge seal Type C, Arrangement 2

- Type 3609HTC – Dual pressurized rotating bellows cartridge seal Type C, Arrangement 3

These dependable API 682 cartridge seals utilize two impressive design innovations by incorporating high-temperature corrosion resistant sealing (HTC) and unique high-temperature live-loaded (HTL) mating ring technology in dual seal arrangements. This new design vastly enhances seal face stability over conventional designs and can extend mean time between repair (MTBR) in many services.

Exceptional Face Stability

The HTC primary seals, patent pending, incorporate specially designed pressure compensating seal faces and thermally

compliant components that provide superior seal face stability at elevated temperatures. With advanced HTL mating ring design, patent pending, seal face stability is achieved by eliminating any thermal and mechanical forces that can contribute to seal face distortion. The sealing interface remains

exceptionally stable in spite of thermal changes and adapts to the wide range of temperature excursions inherent in hightemperature applications.