ipp3 Main applications

The Packo high pressure pumps of the IPP3 series are used primarily in the reverse osmosis (RO) applications for the filtration of, for example, contaminated CIP-water, whey, etc. They are also used as a booster pump in a variety of skids.

You will find them in just about all industries including the dairy industry, breweries, beverage industry as well as in water treatment industry.

IPP3 Design

The Packo stainless steel pumps of the IPP3 series are pumps made of solid, machined stainless steel 316L and are extremely suitable for high system pressure applications up to 40 bar.

IPP3 benefits pump

- Suitable for system pressure applications up to 40 bar

- High pump efficiency resulting in lower energy consumption

- Low NPSH values: less risk on cavitation

- Electropolished: higher resistance against corrosion

- Easy and robust construction and easy maintenance: less downtime

- Standard components

- Easy to install

- 1 mechanical seal diameter for the entire range

IPP3 Description

The Packo stainless steel centrifugal pumps of the ipp3 series are a low-cost industrial pump used for handling pure as well as slightly contaminated products up to 500 cP. They are often used as process pump for the colouring of textiles, for water treatment but also for handling solvents, alcohols and chemicals.

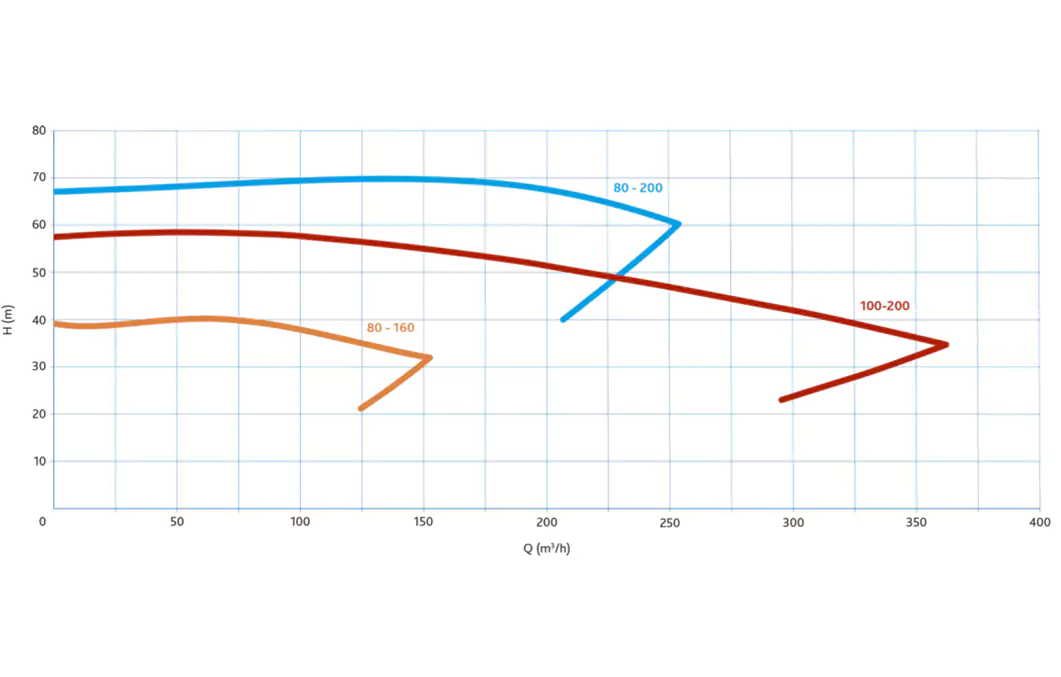

IPP3 Curve

Overview of technical data IPP3

| Max. flow | 350 m3/h |

| Differential head | 70 m wc |

| Max. Inlet pressure | 40 bar |

| Viscosity | 1000 cP |

| Max. temperature | 140 °C |

| Impeller type | Closed |

| Max. free passage | 17 mm |

| Max. drive power | 45 kW |

| Speed | 3000/3600 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 316L or similar |

| Mechanical seal configuration | Single balanced, quench, double seal |

| Available O-ring materials | EPDM, FKM, FEP-FKM, FFKM, Silicone |

| Connections | Flanges according to EN1092-1/11 PN40. Tri-Clamp fittings. etc. |

| Surface Finish | Industrial, internal welds not hand polished, electropolished |

| Certificates | 1935/2004 EC. FDA. EAC |