IML Main applications

They are used in applications for liquids which are difficult to seal with a mechanical seal.

The Packo submersible cantilever pump series IML are used in a wide range of industries and applications such as metal finishing industry, industrial spray washers, water treatment, galvanizing and coating industry, chemical industry, etc.

They are handling degreasing, pickling & phosphatizing liquids, slurries, hot oils, process and industrial wastes, corrosive liquids, condensate, etc.

IML Design

The Packo submersible cantilever pump series IML are designed for installation in a sump or tank, having only the casing and impeller submerged. Because the absence of a mechanical seal and slide bearing in contact with the liquid, the cantilever pumps are maintenance friendly and reduce the downtime. These robust pumps have stainless steel 316L pressed or investment cast pump casings and can be equipped with open, semi-open, closed and vortex impellers. Thanks to its solid construction and electropolished design these pumps are the reliable component for your production process. Available in NP, ICP, MCP, IFF and MFF version with open, semi-open, closed or vortex impellers. The Packo submersible cantilever pump series IML are used in a wide range of industries and applications such as metal finishing industry, industrial spray washers, water treatment, galvanizing and coating industry, chemical industry, etc.

IML benefits pump

- Cantilever design = leakage free, no seals and plain bearings

- Sealless pump: reducing downtime and operating costs

- Not sensitive for dry running

- Easy construction

- Electropolished: higher resistance against corrosion and sticky liquids

- Robust design

- Available with different impellers

IML Description

The Packo submersible cantilever pump series IML are designed for installation in a sump or tank, having only the casing and impeller submerged. Because the absence of a mechanical seal and slide bearing in contact with the liquid, the cantilever pumps are maintenance friendly and reduce the downtime. These robust pumps have stainless steel 316L pressed or investment cast pump casings and can be equipped with open, semi-open, closed and vortex impellers. Thanks to its solid construction and electropolished design these pumps are the reliable component for your production process. Available in NP, ICP, MCP, IFF and MFF version with open, semi-open, closed or vortex impellers. The Packo submersible cantilever pump series IML are used in a wide range of industries and applications such as metal finishing industry, industrial spray washers, water treatment, galvanizing and coating industry, chemical industry, etc.

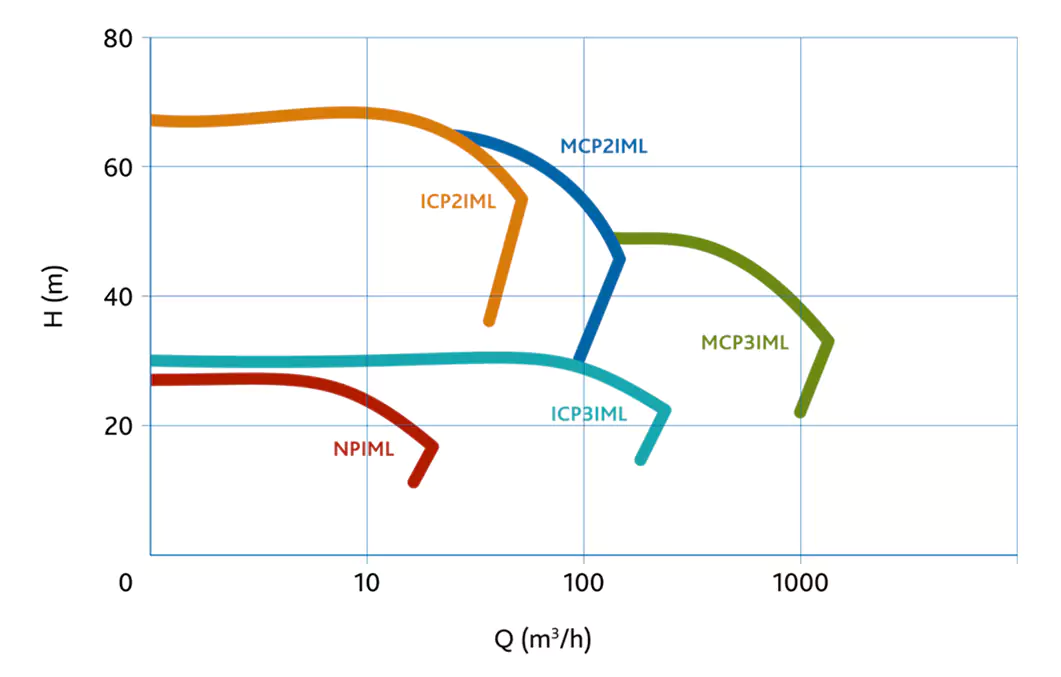

IML Curve

Overview of technical data IML

| Max. flow | 1000 m3/h |

| Differential head | 60 m wc |

| Max. Inlet pressure | – |

| Viscosity | 1000 cP |

| Max. temperature | 200 °C |

| Impeller type | Open. semi-open. closed or vortex |

| Max. pump length | 500 mm |

| Max. free passage | 45 mm |

| Max. drive power | 132 kW |

| Speed | 3000/3600 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 316L or similar |

| Mechanical seal configuration | No seal – cantilever |

| Available O-ring materials | EPDM, FKM |

| Connections | Hygienic fittings. BSP fittings. flanges according to EN1092-1/01 & 02. ANSI flanges |

| Surface finish | Industrial, welds not hand polished, electropolished |

| Certificates | 1935/2004 EC. FDA. EAC. ATEX |