ICP2 Main applications

The highly efficient stainless steel Packo centrifugal pump series ICP2 are used in about all kind of industries such as vegetable industry, breweries, water treatment and textile industry as well as in e.g. biogas, biodiesel and bioethanol applications. Typical liquids are blanching water, mash, wort, process and contaminated water, biodiesel, bioethanol, alcohols, CIP, biogas, etc.

icp2 Design

These robust pumps have stainless steel 316L pump casings constructed in thick cold rolled plate and have open investment cast impellers in stainless steel 316L or duplex materials. Thanks to its solid construction and electropolished design these pumps are the reliable component for your production process.

icp2 benefits pump

- High pump efficiency resulting in lower energy consumption

- Low NPSH values: less risk on cavitation

- Electropolished: higher resistance against corrosion

- Easy & robust construction and easy maintenance: less downtime

- Easy to install

- Solid impellers compared to low cost spot welded versions

2 mechanical seal diameters for entire range - Standard components

icp2 Description

The highly efficient stainless steel Packo centrifugal pump series ICP2 are used in about all kind of industries such as vegetable industry, breweries, water treatment and textile industry as well as in e.g. biogas, biodiesel and bioethanol applications. Typical liquids are blanching water, mash, wort, process and contaminated water, biodiesel, bioethanol, alcohols, CIP, biogas, etc.

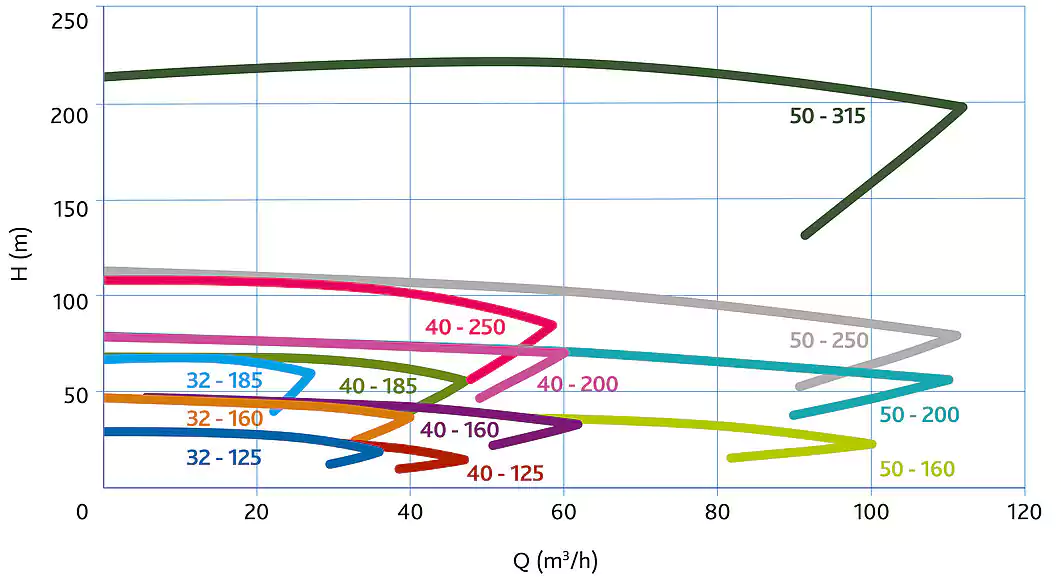

ICP2 Curve

Overview of technical data ICP2

| Max. flow | 110 m3/h |

| Differential head | 220 m wc |

| Max. Inlet pressure | 13 bar |

| Viscosity | 1000 cP |

| Max. temperature | 140 °C |

| Impeller type | Open |

| Max. free passage | 22 mm |

| Max. drive power | 90 kW |

| Speed | 3000 / 3600 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 316L or similar |

| Mechanical seal configuration | Single bellow, single balanced, quench, double, pressurized barrier |

| Available O-ring materials | EPDM, FKM, FEP-FKM, FFKM, Silicone |

| Connections | BSP fittings. flanges according to EN1092-1/01 & 02. ANSI flanges. smooth tubes |

| Surface finish | Industrial, internal welds not hand polished, electropolished |

| Certificates | MEI. ATEX. EAC |