Main applications hgc

- Auxiliary Systems

- Boiler feed systems

- Energy

- General Processes

- Industry engineering

- Mining

- Nuclear Power Stations

- Power Stations < 100 MW

- Power Stations > 100 MW

- Process

- Snow guns

- Steel

- Turbine Island

Design hgc

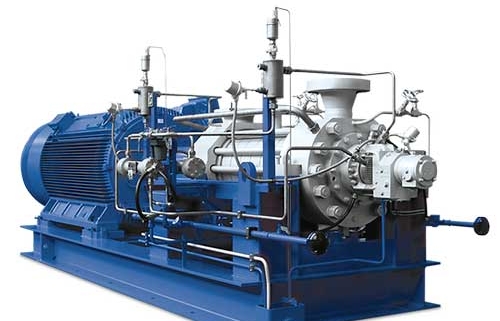

Horizontal radially split ring-section pump with radial impellers, single-entry or double-entry, multistage.

Application pump hgc

Pumping feed water and condensate in power stations and industrial plants, pressurised water generation for bark peeling and descaling units, snow guns, etc.

Technical data

- Q max 1,650.0 m³/h

- H max 4,200.0 m

Drive pump hgc

Direct by electric motor, turbine or combustion engine, or indirect through a gearbox, hydraulic coupling or variable speed coupling.

Desing Details pump hgc

Shaft Seal

Packed stuffing box uncooled or cooled.

Mechanical seal uncooled, with jacket cooling, seat ring cooling, injection or circulation.

The shaft is provided with exchangeable shaft sleeve in the shaft seal area.

Thrust Bearing, Lubrication

Rolling element bearing cooled, oil ring lubrication (HG 1–3)

Plain bearing, forced oil lubrication (HG 1–6)

Flanges

Connection dimensions according to EN or ASME.

Overview of technical data hgc

| Q (50Hz) | 15.0 – 1,650.0 (m³/h) |

| H (50Hz) | 300.0 – 4,200.0 (m) |

| Type of bearing | Rolling element and plain bearings |

| Casing partition | Radially split |

| Drive frequency | 50 Hz /60 Hz |

| Type of drive | Electric motor, turbine |

| Drive voltage | Low voltage, high voltage |

| Type of first impeller | Single entry / Double entry |

| No. of impeller entries | Single / Double entry |

| Other impeller types | Closed / Radial |

| Type of installation | Long-coupled |

| Type of coupling | Direct, Variable speed coupling, Gear, Geared variable speed coupling |

| Type of lubrication | (forced) oil lubrication |

| Max. permissible fluid temperature | 200.0 (°C) |

| Nozzle position | Variable |

| Maximum operating pressure | PN 250, PN 320, PN 400, PN 500 |

| Pump set location | Dry installed |

| Suction characteristics | Non-priming |

| Type of connection | Flange |

| Type of discharge casing | Annular casing |

| Type of stage casing | Stage casing with diffuser |

| Type of suction casing | Annular casing |

| eClass assignment | 36410100, 36410000, 36410101 |

| Installation position | Horizontal |

| Shaft seal type | Mechanical seal, Gland packing |

| Main applications | Industry and process engineering, Energy |

| Casing material | Chrome steel |

| Maximum discharge-side pressure | 420.0 (bar) |

| Maximum suction pressure | 30.0 (bar) |

| Maximum drive rating | 15000.0 (kW) |

| Type of installation | Stationary |

| Maximum speed of rotation | 7000.0 (1/min) |