FMS Main applications

For use in food, brew, beverage, pharmaceutical and chemical industries, as transfer and mixing pump for liquid food products, drinks, medicines, lotions, etc.

Typical applications: process pump for plate heat exchangers, pasteurizer systems, filters, filling machines, mixers, deaerators, carbonators and high pressure cleaning systems.

FMS Design

The hygienically executed Packo multistage pumps from the FMS series are used as process pump in the most diverse applications in food (milk, beer, soft drinks, …), pharmaceutical and chemical industries and this for food, beverages, medicines, lotions, etc. Typical applications are found in filtration, pasteurization, filling machines, high pressure CIP systems, process pump for plate heat exchangers, etc.

FMS benefits pump

- Ideal for operation at moderate flow rate and high pressures

- High pump efficiency resulting in lower energy consumption

- Low NPSH values: less risk on cavitation

- Electropolished: easy to clean

- Easy construction and easy maintenance: less downtime

- Standard components

- Easy to install

FMS Description

The hygienically executed Packo multistage pumps from the FMS series are used as process pump in the most diverse applications in food (milk, beer, soft drinks, …), pharmaceutical and chemical industries and this for food, beverages, medicines, lotions, etc. Typical applications are found in filtration, pasteurization, filling machines, high pressure CIP systems, process pump for plate heat exchangers, etc.

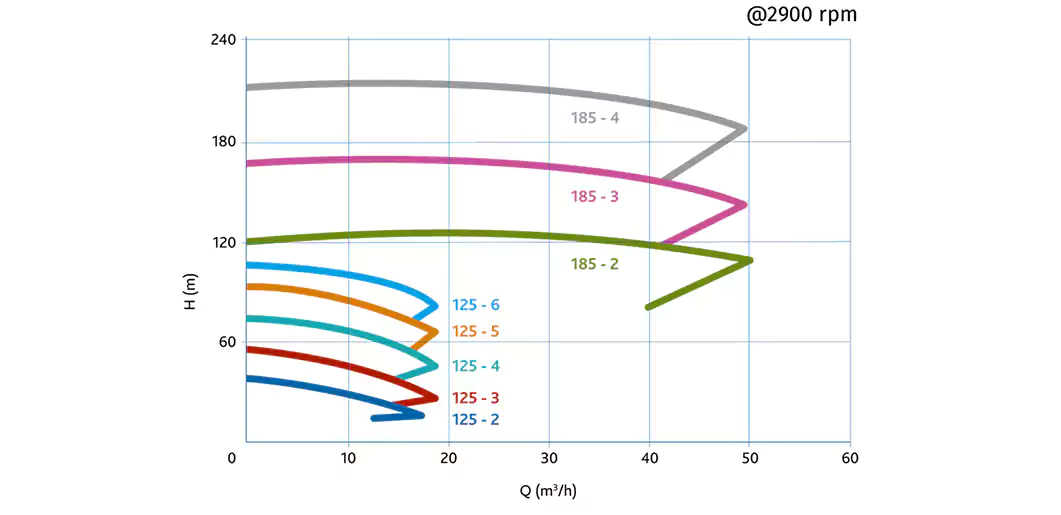

FMS Curve

Overview of technical data FMS

| Max. flow | 50 m3/h |

| Differential head | 215 m wc |

| Max. Inlet pressure | 10 bar |

| Viscosity | 250 cP |

| Max. temperature | 140 °C |

| Impeller type | Open |

| Max. free passage | 14 mm |

| Max. drive power | 45 kW |

| Speed | 3000 / 3600 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 316L or similar |

| Mechanical seal configuration | Single, quench, double |

| Available material O-ring | EPDM, FKM |

| Connections | Hygienic fittings |

| Surface finish | Hygienic quality, internal welds hand polished + electropolished |

| Certificates | 1935/2004 EC. ATEX. FDA. EAC |