About Pump DWO

Centrifugal pump with open impeller in AISI 304 stainless steel made by hydroforming. The radial flow impeller also makes it suitable for pumping liquids that are not completely clean but with solid parts up to 19 mm in diameter

Features

- Compact dimensions

- Sturdy construction

- Silent

description Pump DWO

Centrifugal pump fitted with an open radial flow impeller in AISI 304 stainless steel, also making it suitable for pumping liquids that are not completely clean, but with solid parts up to 19 mm in diameter.

The DWO electric pump’s pressed AISI 304 pump body is obtained through the hydroforming process, providing sturdy construction, hydraulic efficiency and reliability.

For further technical information see the Databook

- Washing of vegetables, meat, fish and molluscs

- Industrial end-of-cycle washing systems, washing and surface finishing of metal pieces, cans, washing of bottles, jars, glass containers, crates, and baskets, etc.

- Communal dishwashers, glasswashers, cup washers, spray booths

- Liquid handling, evacuation and transfer

Overview of technical data DWO

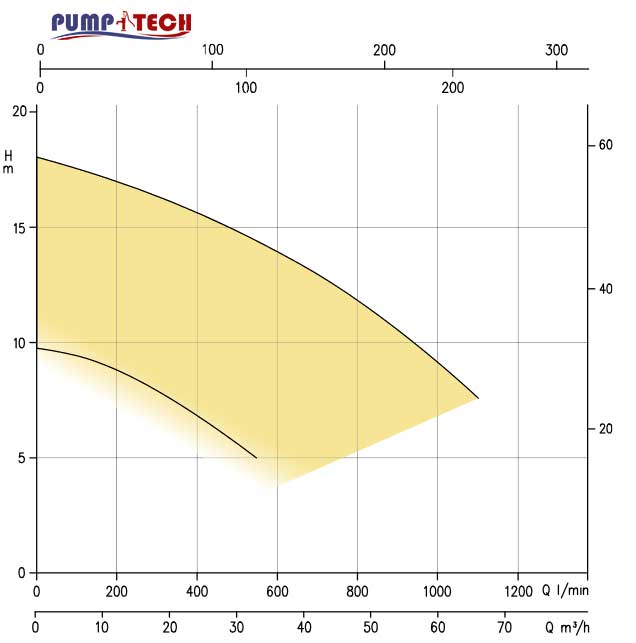

| Flow rate | from 6 to 66 m³/h |

| Total head | 17.5 to 5.1 m |

| Max. working pressure | 8 bar |

| Max. temperature of the liquid | 15°C ÷ +90°C for std version -15°C ÷ +110°C for H, HS, HW, HSW versions |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP55 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~230/400V ±10% |

Material Pump DWO

| Pump body | Stainless steel AISI 304 (EN 1.4301) |

| Impeller | Stainless steel AISI 304 (EN 1.4301) |

| Shaft | Stainless steel AISI 304 (EN 1.4301) |

| Mechanical seal | Standard = Ceramic/Carbon/NBR H = Graphite/Ceramic/FPM HS = Silicon Carbide/Silicon Carbide/FPM HW = Tungsten Carbide/Tungsten Carbide/FPM HSW = Silicon Carbide/Tungsten Carbide/FPM |

| Motor support | Aluminium |

pump DWO

Open impeller centrifugal electric pumps in stainless steel AISI 304

Centrifugal surface electric pumps with molded AISI 304 body, obtained through the hydroforming process: this process exploits the water pressure to deform the material. This guarantees the highest quality standards, the drastic reduction of welding points, the ability to shape the pump body ensuring the most efficient form absolutely and the ability to work steel with high thickness ensuring maximum construction strength.

It mounts the open radial flow impeller, which makes it suitable for pumping liquids that are not completely clean, but with solid parts up to 19 mm in diameter: this is the case of machinery such as washers, car washes, industrial dishwashers to name but a few.

The standard mechanical seal is in Ceramic/Carbon/NBR, and are then available in the versions with special seals.

Technical

- Total head from 17.5 to 5.1 m

- Capacity from 6 to 66 m3/h

- IE3 high efficiency motors starting from 0.75 kW

- Liquid temperature: from -5°C to +90°C (from -15°C to +110°C for H, HS, HW and HSW versions)

- Liquid with solids up to 19 mm in diameter

| Q=Capacity | Absorbed current (A) | Capacitor | KW | Pump type | ||||||||||||

| 1100 | 950 | 750 | 550 | 400 | 300 | 200 | 100 | l/min | Three-phase | Single -phase | Vc | µF | Tree-phase 230/400v 50Hz | Single-phase 230v 50Hz | ||

| 66 | 57 | 42 | 33 | 24 | 18 | 12 | 6 | m/h | 400V | 230V | ||||||

| H= Total head | ||||||||||||||||

| – | – | – | 5.1 | 6.9 | 7.9 | 8.9 | 9.5 | 2.5 | 4.4 | 6.8 | 450 | 31.5 | 1.1 | DWO 150 | DWO 150 M | |

| – | – | 5.8 | 8.6 | 10.5 | 11.5 | 12.3 | 12.7 | 3.5 | 6.1 | 9.0 | 450 | 40 | 1.5 | DWO 200 | DWO 200 M | |

| – | 7.5 | 9.7 | 11.7 | 12.9 | 13.8 | 14.5 | 15 | 4.8 | 8.3 | – | – | – | 2.2 | DWO 300 | – | |

| 7.6 | 9.8 | 12.4 | 14.3 | 15.6 | 16.3 | 16.9 | 17.5 | 6.4 | 11.0 | – | – | – | 3.0 | DWO 400 | – | |