About Pump CMA-B-C-D

Single-impeller centrifugal pump with cast iron body, available in different models: CMA – CMB – CMC – CMD. Depending on the model, the impellers, shafts and motor mount can be made of different materials (see technical data table)

Features

- Available with brass impeller

description Pump CMA-B-C-D

Single-impeller centrifugal pump with cast iron body, available in different models: CMA – CMB – CMC – CMD.

Depending on the model, the impellers, shafts and motor mount can be made of different materials (see technical data table). Their compact size makes CMA-B-C-D centrifugal electric pumps easy to install even when spaces are narrow or difficult to reach.

Their sturdy and reliable structure allows for high performance in all water handling applications.

For further technical information see the Databook

- Pressurisation of domestic installations

- Small-scale irrigation

- Washing systems and vehicle washing

- Handling of non-aggressive liquids for civil and industrial use

Overview of technical data CMA-B-C-D

| Flow rate | from 1.2 to 60.5 m³/h |

| Total head | From 5.2 to 57.0 m |

| Max. working pressure | 6 bar for CMA 0.50-0.75-1.00 CMB 0.75-1.00-1.50-2.00-3.00 CMC, CMD 8 bar for CMA 1.50-2.00-3.00 CMB 4.00-5.50 |

| Max. temperature of the liquid | +40°C for CMA 0.50-0.75-1.00 +90°C for the rest of the range |

| MEI | > 0.4 |

| Poles | 2 |

| Insulation class | F |

| Protection degree | IP44 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~230/400V ±10% |

Material Pump CMA-B-C-D

| Pump body | Cast iron |

| Impeller | in PPE+PS with glass fibres for CMA 0.50 – 0.75 – 1.00 in brass for CMA 1.50 – 2.00 – 3.00 CMB 2.00 – 3.00 – 4.00 – 5.50 in cast iron for CMB 0.75 – 1.00 – 1.50, CMC, CMD |

| Shaft | in AISI 416 (EN 1.4005) (integral) for CMA 0.50 in AISI 303 (EN 1.4305) (part in contact with liquid) for CMA 0.75-1.00-1.50-2.00-3.00 CMB 0.75-1.00-1.50-2.00-3.00 CMC 0.75-1.00, CMD 1.50-2.00-3.00 in AISI 304 (EN 1.4301) (part in contact with liquid) for CMB 4.00-5.50 |

| Mechanical seal | Ceramic/Carbon/NBR (standard) |

| Motor support | in aluminium for CMA 0.50-0.75-1.00 CMB 0.75-1.00 CMC 0.75-1.00 in cast iron for the rest of the range |

pump CMA-B-C-D

Cast iron single impeller centrifugal electric pumps

CM series electric pumps are single impeller electric pumps with cast iron body. Within the series

there are several models: CMA – CMB – CMC – CMD and the CMR model that has the peculiarity of

being equipped with an open impeller. They are equipped with a mechanical seal in Ceramic/Carbon/

NBR. Depending on the models, the impellers can be made of PPE + PS reinforced with fibre glass,

brass or cast-iron. The shafts can be in AISI 416, AISI 303 steel or, alternatively, in AISI 304. The

supports available are in aluminium or cast iron. The motors combined with these electric pumps are

2-pole self-ventilated asynchronous motors and IE3 high efficiency starting from 0.75 kW.

Technical

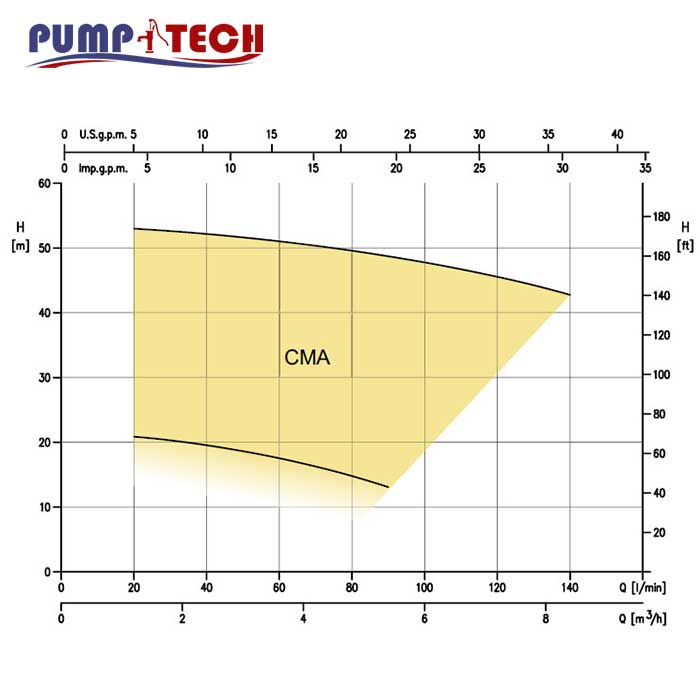

- Prevalence:

– for CMA from 13.1 to 53 m

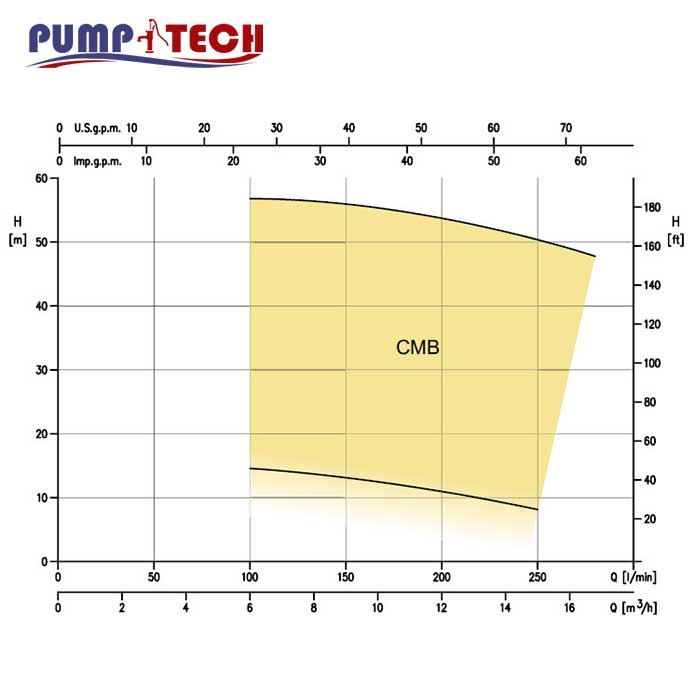

– for CMB from 8.1 to 57 m

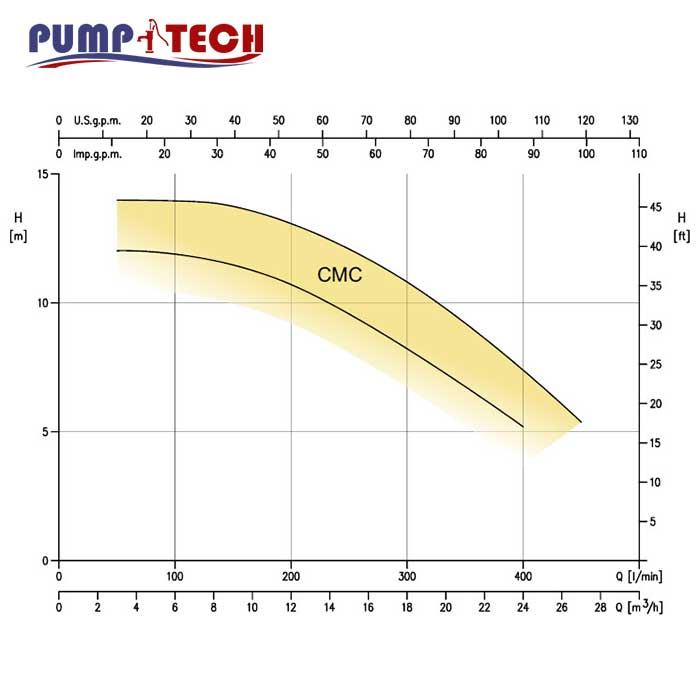

– for CMC from 5.2 to 14 m

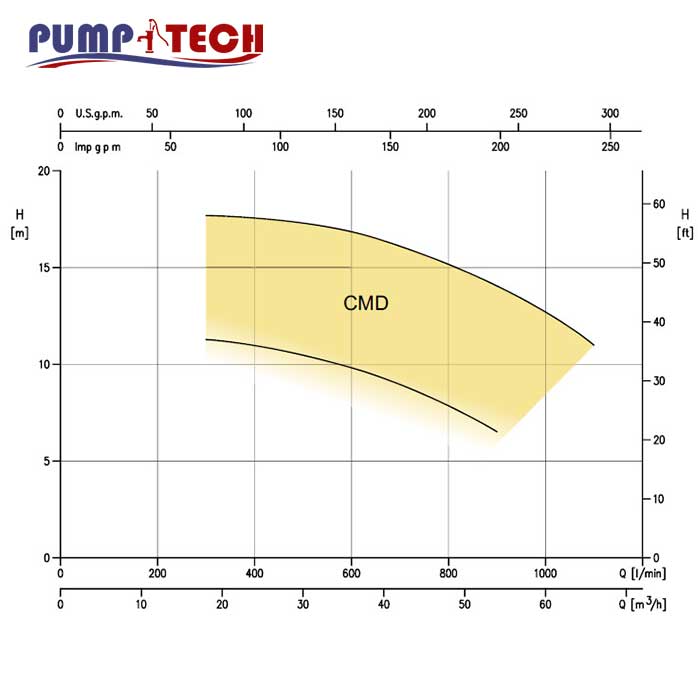

– for CMD from 6.5 to 16,1 m

– for CMR from 6.3 to 17.3 m - Flow rate:

– for CMA from 1.2 to 8.4 m3/h

– for CMB from 6 to 19.9 m3/h

– for CMC from 3 to 27.1 m3/h

– for CMD from 18.1 to 60.2 m3/h

– for CMR from 3 to 16.5 m3/h - Maximum operating pressure:

– 6 bar for CMA 0.50 – 0.75 – 1.00, CMB 0.75 – 1.00 – 1.50 – 2.00 – 3.00,

CMC, CMD, CMR

– 8 bar for CMA 1.50 – 2.00 – 3.00, CMB 4.00 – 5.50 - Maximum liquid temperature:

– 40°C for CMA 0.50 – 0.75 – 1.00

– 90°C for the rest of the range

| Pump Type | KW | Capacitor | Absored Current (A) | Q=Capacity | |||||||||||||||

| 1P | 3P | µF | Vc | Single phase | Three-phase | l/min | 20 | 40 | 60 | 80 | 85 | 90 | 95 | 100 | 110 | 120 | 140 | ||

| 230V | 400V | m/h | 1.2 | 2.4 | 3.6 | 4.8 | 5.1 | 5.4 | 5.7 | 6 | 6.6 | 7.2 | 8.4 | ||||||

| H=Total Head | |||||||||||||||||||

| CMA 0.50 M | CMA 0.50 T | 0.37 | 10 | 450 | 3.2 | 2.4 | 1.4 | 20 | 17.8 | 15 | 12.1 | 11.2 | 10.5 | – | – | – | – | – | |

| CMA 0.75 M | CMA 0.75 T | 0.55 | 16 | 450 | 4.7 | 3.2 | 1.8 | 31.5 | 28.2 | 24 | 18.9 | 17.5 | – | – | – | – | – | – | |

| CMA 0.80 M | CMA 0.80 T | 0.6 | 16 | 450 | 4.8 | 3.3 | 1.9 | 28 | 26.1 | 23.8 | 20.9 | 20.1 | 19.3 | 18.5 | – | – | – | – | |

| CMA 1.00M | CMA 1.00 T | 0.75 | 20 | 450 | 6.2 | 4.3 | 2.5 | 34.5 | 32.8 | 30.6 | 28.2 | 27.6 | 26.9 | 26.2 | 25.5 | – | – | – | |

| CMA 1.50 M | CMA 1.50 T | 1.1 | 35 | 450 | 8 | 5.4 | 3.1 | 40.5 | 39.6 | 38.2 | 36.5 | 36 | 35.6 | 34.9 | 34.3 | 33 | – | – | |

| CMA 2.00 M | CMA 2.00 T | 1.5 | 40 | 450 | 10.3 | 7.5 | 4.3 | 47 | 45.8 | 44.2 | 42.4 | 41.9 | 41.4 | 40.9 | 40.3 | 39.2 | 38 | – | |

| CMA | CMA 3.00 T | 2.2 | – | 9.5 | 5.5 | 53 | 51.8 | 50.2 | 48.3 | 47.8 | 47.3 | 46.7 | 46.2 | 45 | 43.7 | 41 | |||