Design Features mechanical seal Type 5281 (W, D, G, GD)

- Dual cartridge seal designed according to hygienic design criteria (QHD) with inboard rotating seat for optimal

cleaning in place - Squared PTFE-based secondary sealing elements improve

cleaning and support a broad application range - Product wetted materials compliant with FDA requirements

- Special designs and material options such as USP class VI

compliant polymers are available on request - Reverse pressure capabilities inboard

- Suitable for application in explosive areas. Certificates of

conformity according to European Directive 94/9/EC (ATEX) Cat. 1,

2 and 3 available on request

Main applications Amaline

- Advanced treatment / 3.stage

- Bio. treatment / 2.stage

- General Processes

- Industrial waste water

- Snow guns

- Suspended solids treatment

- Waste water

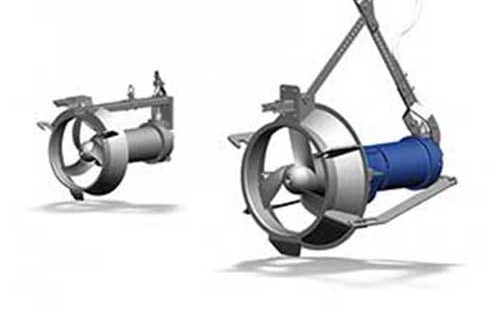

Design Amaline

Wet-installed horizontal propeller pump with submersible motor, equipped with direct drive or spur gear, ECB propeller with three rigid, fibre-repellent blades, bolt-free connection to the discharge pipe. ATEX-compliant version available.

Application pump Amaline

Recirculating activated sludge in waste water treatment systems.

Drive pump Amaline

- Three-phase asynchronous squirrel-cage motor

- Type of protection Ex db IIB (applies to explosion-proof

pump sets only)

Amaline 200, 300, 400: - Direct drive

Amaline 500, 600, 800: - Spur gear drive

Desing Details pump Amaline

Design

- Fully floodable submersible motor pump

- Horizontal installation

- Wet installation

Axial propeller

- Self-cleaning ECB propeller

Shaft seal

- Two bi-directional mechanical seals in tandem

arrangement, with liquid reservoir

Amaline 500, 600, 800: - Additional leakage chamber between the seat ring holder

and the gear unit

Bearings

- Amaline 200, 300, 400:

- Grease-packed rolling element bearings sealed for life

Amaline 500, 600, 800: - Grease-packed rolling element bearings sealed for life in

motor - Oil-lubricated rolling element bearings in gear unit

Overview of technical data Amaline

| Type of bearing | Rolling element bearings |

| Drive | Electric motor |

| Drive frequency | 50 Hz /60 Hz |

| Type of drive | Electric motor |

| Drive voltage | Low voltage |

| Connection to power supply | 400 V, 3~ |

| Explosion protection | ATEX II 2GEXDCIIBT4 |

| Type of coupling | Direct, Gear |

| Type of lubrication | Grease lubrication |

| Max. permissible fluid temperature | 40.0 (°C) |

| Pump set location | Wet well |

| Self-cleaning | Yes |

| eClass assignment | 00000000 |

| Installation position | Horizontal |

| Shaft seal type | Mechanical seal |

| Main applications | Waste water / sewage |

| Maximum drive rating | 16.0 (kW) |

| Type of installation | Stationary |

| Minimum propeller diameter | 800.0 (mm) |

| Maximum speed of rotation | 960.0 (1/min) |