Applications mechanical seal 4ktm

waste water containing stringy material and abrasive particles

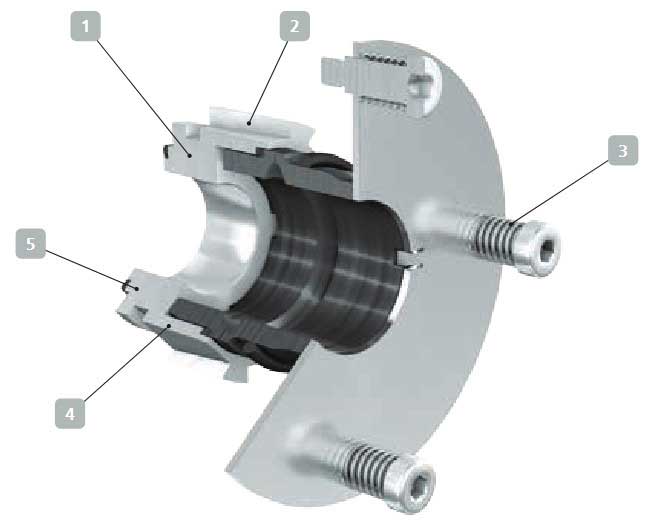

Design mechanical seal 4ktm

- Single mechanical seal

Technical Data mechanical seal 4ktm

- Operating pressure:

Up to 25 bar, dynamic

Up to 37.5 bar, static - Temperature: 0 °C to 130 °C

Benefits mechanical seal 4ktm

Special bi-directional single mechanical seal for seawater applications. The pump’s shaft sleeve is integrated in the mechanical seal.

Stationary design, balanced, multiple springs located outside the fluid handled. The springs are insensitive to contamination and provide uniform surface pressure across the seal faces, thus ensuring a long service life.

The ribs on the shaft sleeve support circulation of the fluid handled in the clearance between the impeller and the pump casing.

Special design mechanical seal 4ktm

Special single mechanical seal for seawater applications, bi-directional, tailored to the seal installation space of the pump.

Circulation mechanical seal 4ktm

The ribs on the shaft sleeve support circulation of the fluid handled in the clearance between the impeller and the pump casing.

Dependable mechanical seal 4ktm

Stationary design, balanced, multiple springs located outside the fluid handled. The springs are insensitive to contamination and provide uniform surface pressure across the seal faces, thus ensuring a long service life.

Compact mechanical seal 4ktm

The pump‘s shaft sleeve is integrated in the mechanical seal.

Service-friendly mechanical seal 4ktm

Easy to install, no adjusting dimension required

Material mechanical seal 4ktm

Primary ring SiC (Q1)

Mating ring SiC (Q1)

Elastomers FKM (V) / FFKM (K)

Springs 2.4610 (M)

Other Components 1.4462 (G1)

Other material combinations on request

Technical data mechanical seal 4ktm

Operating pressure Up to 25 bar, dynamic

Up to 37.5 bar, static

Temperature 0 °C to 130 °C

Bearing bracket (seal size) P03 (031)

Business type Engineered