Applications seal 4es

API 682 applications in the chemical and petrochemical industries

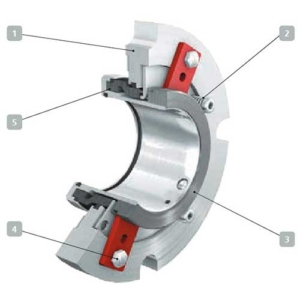

Design mechanical seal 4es

- Single cartridge seal

Technical Data mechanical seal 4es

- Pressure: Up to 20 bar

- Temperature: -75 to 400 °CSingle cartridge seal

Benefits mechanical seal 4es

Single cartridge seal, bi-directional and balanced.

Stationary design, multiple springs located outside the fluid handled.

Tailored to the seal installation space and requirements of the pump, easy installation, no adjusting dimension.

Assembly fixtures ensure optimal pre-loading of the cartridge. The mechanical seal cover is centred on the pump cover.

Compact

Single cartridge seal, bi-directional and balanced.Dependable

Stationary design, multiple springs located outside the fluid handled.Versatile

For all operating conditions the pump is approved for.Service-friendly

Tailored to the seal installation space and requirements of the pump, easy installation, no adjusting dimension. Assembly fixtures ensure optimal pre-loading of the cartridge. The mechanical seal cover is centred on the pump cover.Different material variants

Mating ring made of silicon carbide, “A” carbon (hot water) or “B” carbon. Elastomers in EPDM (also for drinking water ACS / WRAS) or FKM.

Material seal 4edtr6hs & q

- Primary ring: “A“ carbon (A) / SiC-Si (Q2)

- Mating ring: SiC-Si (Q2)

- Secondary sealing elements: Statotherm® (G)

- Metal bellows: Inconel® 718 (M6)

- Other Components: Carpenter® 42 (T4)

Technical data 4edtr6hs & q

- Shaft diameter: 50 to 120 mm

- Pressure: Up to 20 bar

- Temperature: -75 to 400 °C