About Pump BEST 2-5

Submersible pump made entirely of AISI 304 stainless steel, with double mechanical seal in oil chamber, also available with float switch. Possibility of fixed or mobile installation and suitable for domestic applications and large industrial drainage installations

Features

Possibility to use in fixed and mobile installations

description Pump BEST 2-5

Submersible pump entirely in AISI 304 stainless steel, with double mechanical seal in oil chamber.

Practical and easy to use, BEST 2-5 electric pumps are also available with float, thus increasing their versatility of use.

For further technical information see the Databook

- Handling of seepage water

- Emptying of basements, garages, cellars

- Drainage of small and medium-sized construction sites

Overview of technical data BEST 2-5

| Flow rate | from 1.2 to 21.6 m³/h |

| Total head | From 2.9 to 18.4 m |

| Max. temperature of the liquid | +35°C |

| Poles | 2 |

| Max. solids passage | 10 mm |

| Insulation class | F |

| Protection degree | IP68 |

| Voltage | Single-phase 1~230V ±10% Three-phase 3~400 ±10% |

| Max. immersion | 7 m with 10 m cable |

Material Pump BEST 2-5

| Pump body | AISI 304 (EN 1.4301) |

| Impeller | AISI 304 (EN 1.4301) |

| Shaft | Stainless steel AISI 303 (EN 1.4305) (part in contact with liquid) |

| Mechanical seal | upper part in Carbon/Ceramic/NBR (motor side) lower part in Silicon Carbide/NBR (pump side) |

pump BEST 2-5

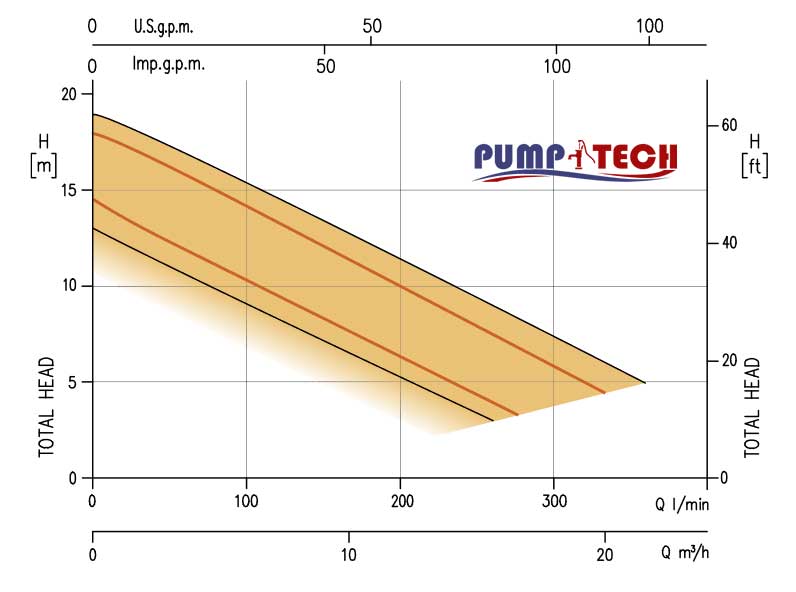

PERFORMANCE CURVE SPECIFICATIONS

The specifications below qualify the curves shown on the following pages.

Tolerances according to ISO 9906:2012 – Grade 3B

The curves refer to effective speed of asynchronous motors at 50 Hz, 2 poles.

Measurements were carried out with clean water at 20°C of temperature and with a kinematic viscosity

of ν = 1 mm2/s (1 cSt)

In order to avoid the risk of over-heating, the pumps should not be used at a flow rate below 10% of best efficiency point.

Symbols explanation:

Q = volume flow rate

H = total head

INSTALLATION

The BEST 2 – 5 electric pumps are also available with a float switch, thus increasing the versatility of use. The choice of the use of the float switch requires the respecting of minimum installation spaces to guarantee correct operation of the pump itself.

Technical

- Total head from 2.9 to 18.4 m

- Capacity from 1.2 to 21.6 m3/h

- Maximum immersion 7 m

- Maximum liquid temperature 35°C

- Maximum solid size passage 10 mm

Submersible pumps in AISI 304

Submersible electric pump completely in AISI 304 stainless steel.

The pump body, the impeller, the suction grille, the motor cover, the seal holder disc and the motor

case are in AISI 304.

The shaft is in AISI 303 (part in contact with the liquid). Double mechanical seal with oil chamber: the

upper one in Carbon/Ceramic/NBR (motor side), the lower one in SiC/SiC/NBR (pump side).

Special Versions

– MA Version with floa

|

Pump type |

KW |

Capacitor |

Absorbed Current (A) |

l/min |

Q=Capacity |

|||||||||||

|

Single-phase 230V 50HZ |

Three-phase 400V 50HZ |

µF |

Vc |

1~ |

3~ |

20 |

80 |

120 |

170 |

260 |

280 |

330 |

360 |

0 |

||

|

m/h |

1.2 |

4.8 |

7.2 |

10.2 |

15.6 |

16.8 |

19.8 |

21.6 |

0 |

|||||||

|

H=Total Head |

||||||||||||||||

|

Best 2 M |

Best 2 |

0.55 |

16 |

450 |

4.4 |

2.0 |

|

12.2 |

9.8 |

8.3 |

6.3 |

2.9 |

– |

– |

– |

– |

|

Best 3 M |

Best 3 |

0.75 |

20 |

450 |

5.6 |

2.4 |

|

13.6 |

11.1 |

9.5 |

7.6 |

4 |

3.2 |

– |

– |

– |

|

Best 4 M |

Best 4 |

1.1 |

31.5 |

450 |

7.3 |

3.0 |

|

17.4 |

15 |

13.4 |

11.3 |

7.5 |

6.7 |

4.6 |

– |

– |

|

Best |

Best 5 |

1.5 |

– |

– |

– |

3.3 |

|

18.4 |

16.1 |

14.5 |

12.5 |

9 |

8 |

3 |

5 |

– |