Features mechanical seal sh-d

- Dual seal in face-to-face arrangement

- Balanced

- Cartridge unit

- Stationary multiple springs

- Shrink-fitted seal rings

- Rugged mating rings

Advantages mechanical seal sh-d

- Engineered seal for extended requirements

- Deformation-optimized seal for high pressure and high sliding velocity

- Insensitive to shaft deflections due to stationary design

- Version with loose-fitted seal rings available, for extreme applications

Operating range mechanical seal sh-d

- Shaft diameter:

d1 = 40 … 110 (250) mm (1.57″ … 4.33 (9.84)” - Pressure:

p1 = 42 (150) bar (609 (2,175) PSI) - Temperature:

t = -40 °C … +176 (+200) °C (-40 °F … +350 (+394) °F) - Sliding velocity:

vg = 23 (60) m/s (76 (197) ft/s) - Axial movement: ±3.0 mm

Materials mechanical seal sh-d

- Seal rings: Blister resistant carbon,

- Silicon carbide SSiC (Q1), RBSiC (Q2, Q3)

- Mating rings:

Silicon carbide SSiC (Q1), RBSiC (Q2) - Secondary seals:

EPDM (E), NBR (P), FKM (V), FFKM (K) - Springs: Hastelloy® C-4 (M)* and C-276 (M5)

- Metal parts: CrNiMo steel 316 (G) or equivalent,

optional materials on request.

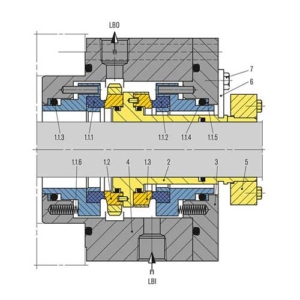

| Item | Description |

| 1.1.1, 1.1.2 | Seal ring |

| 1.1.3, 1.1.4 | O-Ring |

| 1.1.5 | Thrust ring |

| 1.1.6 | Spring |

| 1.2, 1.3 | Mating ring |

| 2 | Seal sleeve |

| 3, 4 | Gland plate |

| 5 | Shrink disk |

| 6 | Setting device |

| 7 | Hexagon bolt |

Recommended applications seal sh-d

- Oil and gas industry

- Refining technology

- Chemical industry

- Hot water

- Sour water

- Caustic soda

- Amines

- Crystallizing media

- Crude oil

- Process water

- Crude oil feed pumps

- Injection pumps

- Multiphase pumps