MFP3 Main applications

The high efficient stainless steel centrifugal pumps of the MFP3 series are used on the most demanding hygienic applications in almost all industries such as dairies, breweries, beverage industry, distilleries, etc. These robust food processing pumps are the ideal reliable component for filtration applications, pasteurization, yeast propagation, evaporating as well as for CIP cleaning systems. Typical applications include filtration of beer, wine and fruit juices as well as pumping yeast, whey and curd.

MFP3 Design

The Packo pumps of the MFP3 series are used on the most demanding hygienic applications in almost all industries such as dairies, breweries, beverage industry, distilleries, etc. These robust pumps have stainless steel 316L cast pump casings and closed investment cast impellers, constructed in 316L or duplex materials.

Thanks to its crevice-free design and electropolishing as a final surface treatment, the MFP3 pump series are the ideal reliable component for your production process.

mfp3 benefits pump

Electropolished, easy to clean construction, no bacteria traps and no small clearances in order to clean the area around the O-ring

Solid design thanks to investment cast casings and impellers

Large seal cavity to clean mechanical seal properly

Monobloc execution with std. IEC motors

mfp3 Description

The high efficient stainless steel centrifugal pumps of the MFP3 series are used on the most demanding hygienic applications in almost all industries such as dairies, breweries, beverage industry, distilleries, etc. These robust food processing pumps are the ideal reliable component for filtration applications, pasteurization, yeast propagation, evaporating as well as for CIP cleaning systems. Typical applications include filtration of beer, wine and fruit juices as well as pumping yeast, whey and curd.

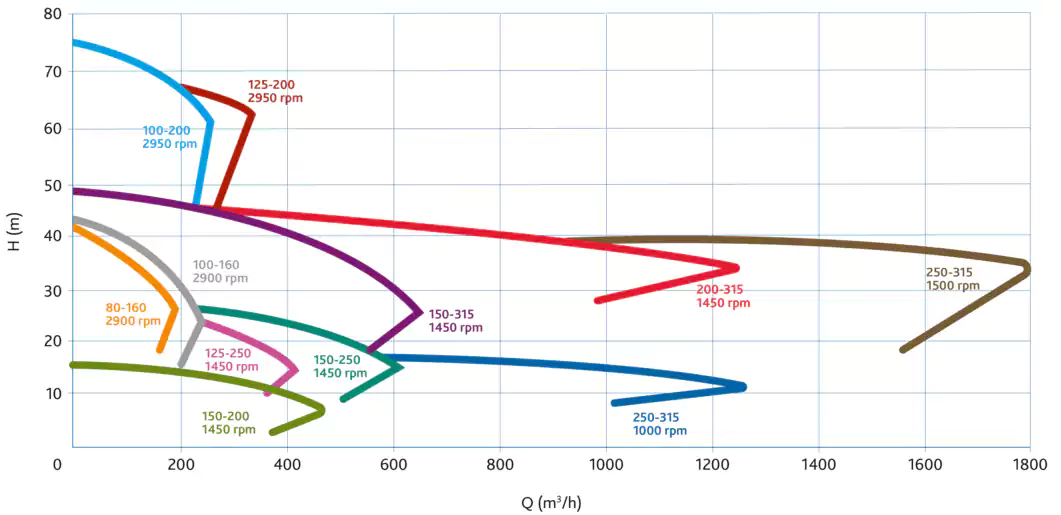

MFP3 Curve

Overview of technical data mfp3

| Max. flow | 1800 m3/h |

| Differential head | 75 m wc |

| Max. Inlet pressure | 12 bar |

| Viscosity | 500 cP |

| Max. temperature | 140 °C |

| Impeller type | Closed with back vanes and balancing holes |

| Max. free passage | 27 mm |

| Max. drive power | 250 kW |

| Speed | 3000 / 3600 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 316L or similar |

| Mechanical seal configuration | Single, quench, double |

| Available material O-ring | EPDM, FKM, FEP-FKM, FFKM, Silicone |

| Connections | Hygienic fittings |

| Surface finish | Hygienic quality, internal welds hand polished + electropolished |

| Certificates | 1935/2004 EC. FDA. USP. ATEX. MEI. EAC |