MFP2 Main applications

These robust process pumps are the ideal reliable component for filtration applications, pasteurization, yeast propagation as well as for CIP cleaning systems.

Typical applications include filtration of beer, wine and fruit juices as well as pumping yeast, whey, curd, CIP, etc.

MFP2 Design

The high efficient stainless steel centrifugal pumps of the MFP2 series are used on the most demanding hygienic applications in almost all industries such as dairies, breweries, beverage industry, distilleries, etc. These robust food processing pumps are the ideal reliable component for filtration applications, pasteurization, yeast propagation, evaporating as well as for CIP cleaning systems. Typical applications include filtration of beer, wine and fruit juices as well as pumping yeast, whey and curd.

MFP2 benefits pump

- High pump efficiency resulting in lower energy consumption

- Low NPSH values: less risk on cavitation

- Electropolished: perfectly cleanable

- Easy construction and easy maintenance: less downtime

- Standard components

- Easy to install

- Robust construction

mfp2 Description

The high efficient stainless steel centrifugal pumps of the MFP2 series are used on the most demanding hygienic applications in almost all industries such as dairies, breweries, beverage industry, distilleries, etc. These robust food processing pumps are the ideal reliable component for filtration applications, pasteurization, yeast propagation, evaporating as well as for CIP cleaning systems. Typical applications include filtration of beer, wine and fruit juices as well as pumping yeast, whey and curd.

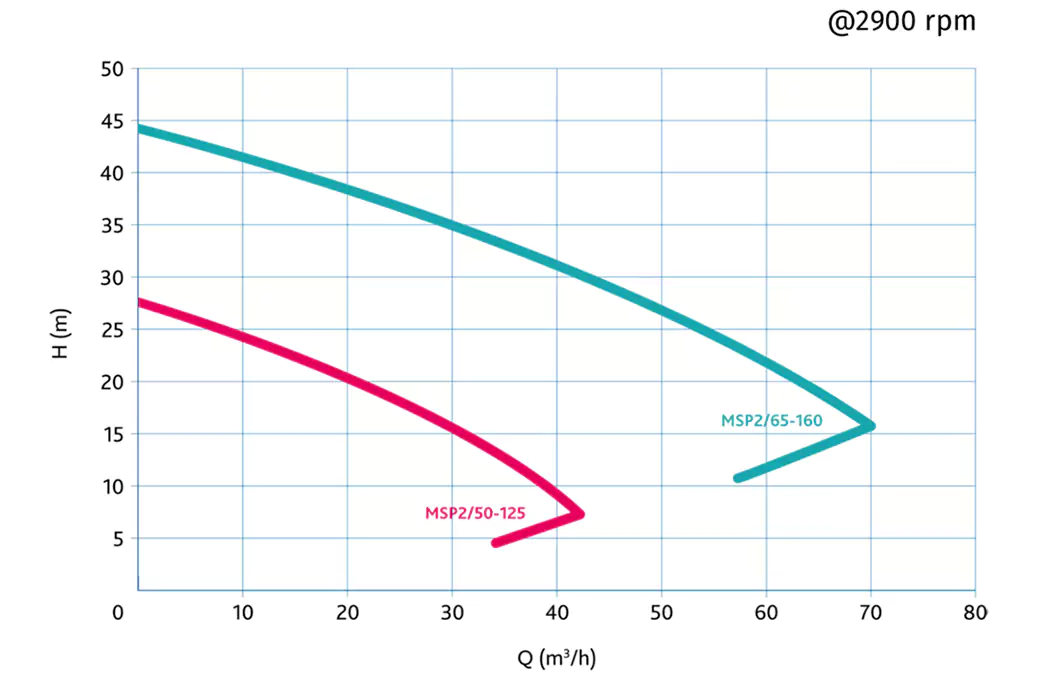

mfp2 Curve

Overview of technical data mfp2

| Max. flow | 120 m3/h |

| Differential head | 65 m wc |

| Max. Inlet pressure | 10 bar |

| Viscosity | 1000 cP |

| Max. temperature | 140 °C |

| Impeller type | Open and semi-open |

| Max. free passage | 25 mm |

| Max. drive power | 22 kW |

| Speed | 3000 / 3600 rpm |

| Available frequency | 50 / 60 Hz |

| Materials wetted parts | Stainless steel 316L or similar |

| Mechanical seal configuration | Single, quench, double |

| Available material O-ring | EPDM, FKM, FEP-FKM, FFKM, Silicone |

| Connections | Hygienic fittings |

| Surface finish | Hygienic quality, internal welds hand polished + electropolished |

| Certificates | 1935/2004 EC. FDA. USP. ATEX. MEI. EAC |