Applications mechanical seal 4esd

- drinking water

- service water

- hot wate

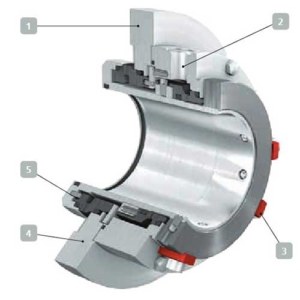

Design mechanical seal 4esd

- Double cartridge seal

Technical Data mechanical seal 4esd

- Operating pressure:

- Up to 16 bar dynamic

- Up to 24 bar static

- Temperature: -30 °C to 140 °C

Benefits mechanical seal 4esd

Double cartridge seal, bi-directional and balanced. Tailored to the seal installation space and pump requirements.

For increased safety levels and dry running protection when the pump is used in suction lift operation.

Stationary: inboard, dynamic: outboard. The double mechanical seal’s cartridge can be operated with either unpressurised buffer fluid (quench) or pressurised barrier fluid.

Compact seal 4esd

Double cartridge seal, bi-directional and balanced. Tailored to the seal installation space and pump requirements.Connections mechanical seal 4esd

G ¼” barrier/buffer fluid inlet, outlet and drain connections.Service-friendly 4esd

The cartridge makes for easy installation, ensuring optimal pre-loading of the mechanical seal and low wear.Applicationsmechanical seal 4esd

For increased safety levels and dry running protection when the pump is used in suction lift operation.Dependable seal 4esd

Stationary: inboard, dynamic: outboard. The double mechanical seal’s cartridge can be operated with either unpressurised buffer fluid (quench) or pressurised barrier fluid.

Material seal 4esd

- Inboard: Primary and mating ring SiC (Q1)

- Outboard: Primary ring 1.4122 (S) Mating ring “B” carbon (B)

- Elastomers: FKM (V) / EPDM (E) / FFKM (K) /

FEP-encapsulated (M1) - Springs: 1.4571 (G)

- Other Components: 1.4571 (G)

Technical data seal 4esd

- Operating pressure: Up to 16 bar dynamic Up to 24 bar static

- Temperatur -30 °C to 140 °C

- Bearing bracket (seal size) 65 (065)

- Business type Engineered