Ana uygulamalar multitec 200 / 250

- Kül giderme

- Bina Servisi

- Kimyasal endüstri

- Soğutma suyu ve yoğuşma suyu

- tuzdan arındırma

- Enerji

- Endüstri mühendisliği

- Sulama

- Enerji Santralleri < 100 MW

- Elektrik Santralleri > 100 MW

- Basınç artırma

- Türbin olarak kullanılan pompalar

- Ham su taşımacılığı

- Sistemler

- su

- Su tedarik etmek

- Su ulaştırma

- İdrar yolları

- Su ulaştırma

- Su arıtma

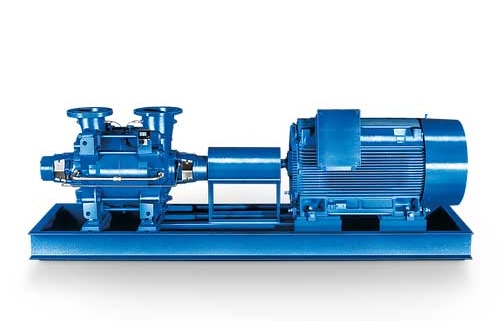

Multitec 200 / 250 tasarımı

Halka kesitli tasarımlı, uzun kaplinli, radyal emme ağızlı, döküm radyal çarklı, çok kademeli yatay santrifüj pompa.

Uygulama pompası multitec 200 / 250

Su ve içme suyu temin sistemleri, basınç yükseltme sistemleri, sulama sistemleri.

Teknik veri

Q max 1,500.0 m³/h

H max 400.0 m

Tahrik pompası multitec 200 / 250

- 50 Hz and 60 Hz electric motor

- Can be driven by diesel engine or turbine

Tasarım Detayları pompa multitec 200 / 250

Design

▪ Multistage centrifugal pump in ring-section design

▪ Horizontal installation in long-coupled or close-coupled design

▪ Vertical installation in close-coupled design or with universal joint shaft

Pump casing

▪ Suction casing: axial or radial

▪ Radial suction casing and discharge casing: nozzles can be turned in steps of 90°

▪ Flanges to EN and ASME (holes and flange facing)

▪ Identical seal housing for gland packing and mechanical seal

▪ Stage casings, discharge casings and seal housing sealed by confined O-rings

Impeller type

▪ Closed radial impeller with multiply curved vanes

Fluids handled

▪ Water

▪ Drinking water

▪ Boiler feed water

▪ High-temperature hot water

▪ Condensate

Bearings

▪ Fixed bearing, drive end, rolling element bearing

▪ Radial bearing, non-drive end, either plain bearing or rolling element bearing, depending on the type of installation

▪ Rolling element bearing grease or oil lubricated

▪ Plain bearing lubricated by fluid handled

▪ Self-aligning

Shaft seal

▪ Uncooled gland packing, with or without barrier fluid

▪ Standardised mechanical seal to EN 12756

▪ Cartridge seal

multitec 200 / 250 teknik verilerine genel bakış

| Q (50Hz) | 110.0 – 1,500.0 (m³/h) |

| H (50Hz) | 110.0 – 400.0 (m) |

| Type of bearing | Rolling element bearings |

| Casing partition | Radially split |

| Diffuser material (EN standard) | CC480K-GS, GJL 250 |

| Drive frequency | 50 Hz /60 Hz |

| Type of drive | Electric motor, turbine, I.C. engine |

| Drive voltage | Low voltage |

| Type of first impeller | Closed / Radial |

| No. of impeller entries | Single entry |

| Other impeller types | Closed / Radial |

| Impeller material (EN standard) | CC480K-GS, GJL 250 |

| Type of installation | Long-coupled |

| Type of coupling | Direct |

| Type of lubrication | grease-/oil- and product lubrication |

| Discharge casing material (EN standard) | GJS 400 |

| Max. permissible fluid temperature | 60.0 (°C) |

| Nozzle position | Variable |

| Maximum operating pressure | PN 16, PN 40 |

| Pump set location | Dry installed |

| Shaft material (EN standard) | 1.4021+QT |

| Stage casing material (EN standard) | GJS 400 |

| Suction casing material (EN standard) | GJS 400 |

| Suction characteristics | Non-priming |

| Type of connection | Flange |

| Type of discharge casing | Annular casing |

| Type of stage casing | Stage casing without diffuser |

| Type of suction casing | Annular casing |

| Casing material (EN standard) | GJS 400 |

| eClass assignment | 36410100, 36410000, 36410101 |

| Installation position | Horizontal |

| Shaft seal type | Mechanical seal, Gland packing |

| Main applications | Water |

| Casing material | Nodular cast iron |

| Maximum discharge-side pressure | 40.0 (bar) |

| Maximum drive rating | 1500.0 (kW) |

| Type of installation | Stationary |

| Maximum speed of rotation | 1750.0 (1/min) |

| Pump size | DN 200, DN 250 |